Nissan Rogue Service Manual: Fuel level sensor signal circuit

Component Function Check

1.COMBINATION METER INPUT SIGNAL

- Select "METER/M&A" on "CONSULT".

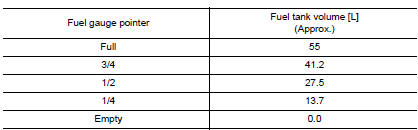

- Using "FUEL METER" of "Data Monitor", compare the value of "Data Monitor" with fuel gauge pointer of combination meter.

Does the data monitor value approximately match the fuel gauge indication? YES >> Inspection End.

NO >> Replace combination meter. Refer to MWI-82, "Removal and Installation".

Diagnosis Procedure

1.CHECK FUEL LEVEL SENSOR UNIT AND FUEL PUMP (FUEL LEVEL SENSOR) CIRCUIT

- Turn ignition switch OFF.

- Disconnect combination meter connector and fuel level sensor unit and fuel pump (fuel level sensor) connector.

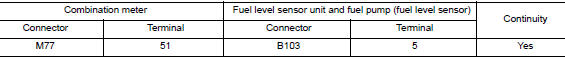

- Check continuity between combination meter harness connector and fuel level sensor unit and fuel pump (fuel level sensor) harness connector.

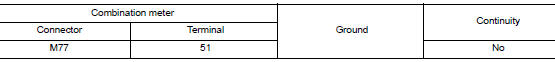

- Check continuity between combination meter harness connector and ground.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair harness or connector.

2.CHECK FUEL LEVEL SENSOR UNIT AND FUEL PUMP (FUEL LEVEL SENSOR) GROUND CIRCUIT

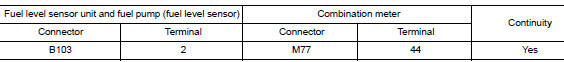

Check continuity between fuel level sensor unit and fuel pump (fuel level sensor) harness connector and combination meter harness connector.

Is the inspection result normal? YES >> Replace combination meter. Refer to MWI-82, "Removal and Installation".

NO >> Repair harness or connector.

Component Inspection

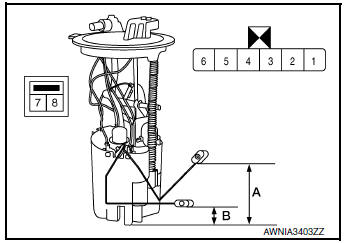

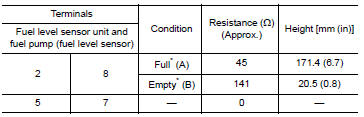

1.CHECK FUEL LEVEL SENSOR UNIT AND FUEL PUMP (FUEL LEVEL SENSOR)

- Remove the fuel level sensor unit and fuel pump (fuel level sensor). Refer to FL-6, "Removal and Installation".

- Check the resistance between fuel level sensor unit and fuel pump (fuel level sensor).

*: When float rod is contact with stopper.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace fuel level sensor unit and fuel pump (fuel level sensor). Refer to FL-6, "Removal and Installation".

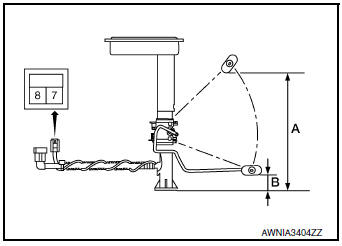

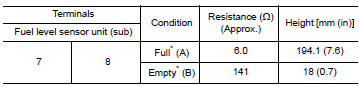

2.CHECK FUEL LEVEL SENSOR UNIT (SUB)

- Remove the fuel level sensor unit (sub). Refer to FL-6, "Removal and Installation".

- Check the resistance between fuel level sensor unit (sub).

*: When float rod is contact with stopper.

Is the inspection result normal? YES >> Inspection End.

NO >> Replace fuel level sensor unit (sub). Refer to FL-6, "Removal and Installation".

Power supply and ground circuit

Power supply and ground circuit

COMBINATION METER

COMBINATION METER : Diagnosis Procedure

Regarding Wiring Diagram information, refer to MWI-32, "Wiring Diagram".

1.CHECK FUSES

Check that the following fuses are not bl ...

Parking brake switch signal circuit

Parking brake switch signal circuit

Description

Transmits the parking brake switch signal to the combination meter.

Component Function Check

1.COMBINATION METER INPUT SIGNAL

Start engine.

Check "PKB SW" in ...

Other materials:

Front wiper drive assembly

Exploded View

REMOVAL

Cowl top

Front wiper drive assembly

Removal and Installation

REMOVAL

Remove cowl top cover. Refer to EXT-25, "Removal and

Installation".

Disconnect harness connector from front wiper motor.

Remove bolts and front wiper driv ...

U1010 control unit (CAN)

Description

Air bag diagnosis sensor performs self-tests on key ON. If CAN communication

failure within control unit is

detected, DTC is set.

DTC Logic

DTC DETECTION LOGIC

CONSULT name

DTC

DTC detecting condition

Repair order

CAN CONTROL UNIT FAILURE

...

System description

STRUCTURE AND OPERATION

Sectional View

Drive gear

Side bearing

Differential case

Pinion mate shaft

Side gear

Pinion mate gear

Drive pinion

Collapsible spacer

AWD solenoid

Stud bolt

Electric controlled coupling

Pinion front bearing

Pinion rear bearing

Elect ...