Nissan Rogue Service Manual: Fluid cooler hose

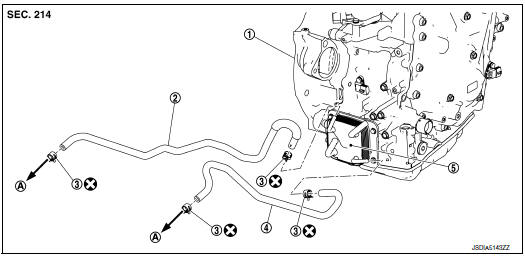

Exploded View

COMPONENT PARTS LOCATION

- Transaxle assembly

- Fluid cooler hose A

- Hose clamp

- Fluid cooler hose B

- CVT oil warmer

- To radiator

: Always replace after every

disassembly.

: Always replace after every

disassembly.

Removal and Installation

REMOVAL

NOTE: When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

- Remove engine under cover. Refer to EXT-37, "ENGINE UNDER COVER : Removal and Installation".

- Remove fender protector side cover. Refer to EXT-28, "FENDER PROTECTOR : Exploded View".

- Remove fluid cooler hoses.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not reuse hose clamp.

- Securely install fluid cooler hose A clip to the radiator core support.

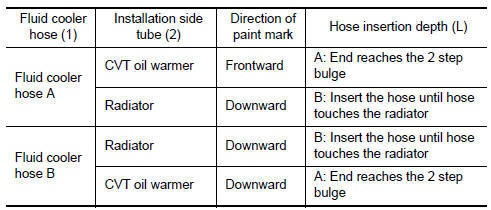

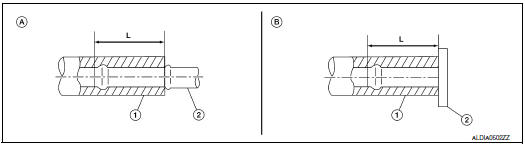

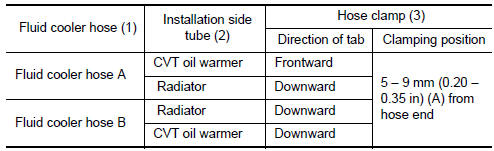

- Refer to the followings when installing fluid cooler hoses.

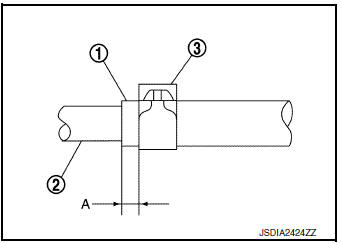

- Refer to the followings when installing hose clamps.

CAUTION: Hose clamp should not interfere with the bulge of tube.

Inspection

INSPECTION AFTER INSTALLATION

Check for CVT fluid leakage and check CVT fluid level. Refer to TM-190, "Inspection".

Water hose

Water hose

Exploded View

Water outlet

Hose clamp

Water hose A

Clip

CVT oil warmer

Transaxle assembly

Water hose B

Heater thermostat

Water hose C

: Always replace after every

di ...

CVT oil warmer

CVT oil warmer

Exploded View

Transaxle assembly

CVT oil warmer

: N·m (kg-m, in-lb)

Removal and Installation

REMOVAL

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns co ...

Other materials:

U1000 CAN COMM circuit

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT

Detection Condition

Possible Cause

U1000

CAN COMM CIRC

[U1000]

When combination meter is not transmitting or receiving CAN

communication signals for 2 seconds or more.

CAN communication system

D ...

Oil

Description

MAINTENANCE OF OIL LEVEL

The compressor oil is circulating in the system together with the

refrigerant. It is necessary to fill compressor

with oil when replacing A/C system parts or when a large amount of refrigerant

leak is detected. It is important

to always maintain oil level ...

Windshield-washer fluid

Windshield-washer fluid reservoir

Fill the windshield-washer fluid reservoir periodically.

Add windshield-washer fluid when the low

windshield-washer fluid warning light comes on.

To fill the windshield-washer fluid reservoir, lift

the cap off the reservoir and pour the windshieldwasher ...