Nissan Rogue Service Manual: Cooler pipe and hose

Exploded View

- Condenser

- High-pressure flexible hose

- Low-pressure flexible hose

- Low-pressure pipe

- Heating and cooling unit assembly

- High-pressure pipe

- Compressor

- O-ring

- Low-pressure service port

- High-pressure service port

LOW-PRESSURE PIP

LOW-PRESSURE PIPE : Removal and Installation

REMOVAL

- Discharge the refrigerant. Refer to HA-23, "Recycle Refrigerant".

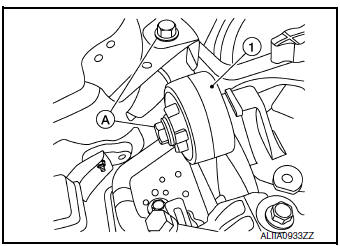

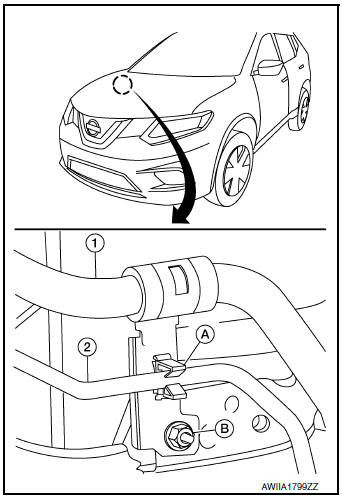

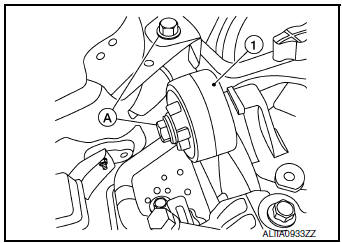

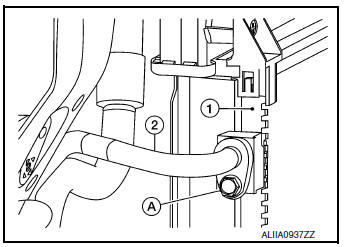

- Remove bolts (A) and engine upper mount (1).

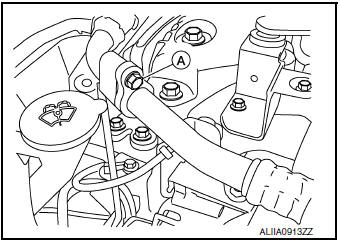

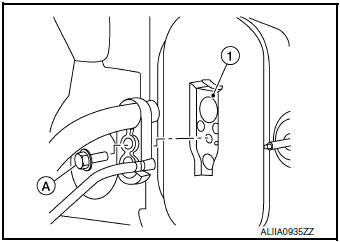

- Remove the bolt (A) that retains the low-pressure flexible hose to the low-pressure pipe.

CAUTION: Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

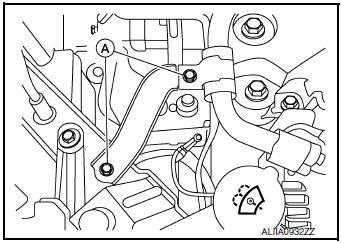

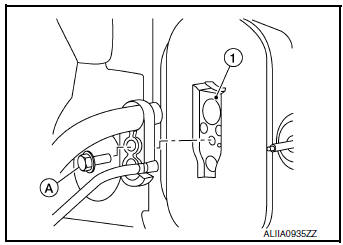

- Remove low-pressure pipe bracket bolts (A) and bracket.

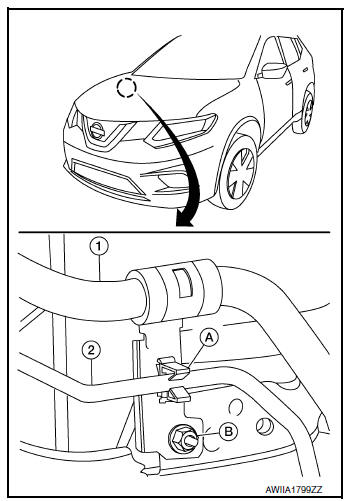

- Release high-pressure pipe (2) from clamp (A).

- Remove nut (B) and low-pressure pipe (1).

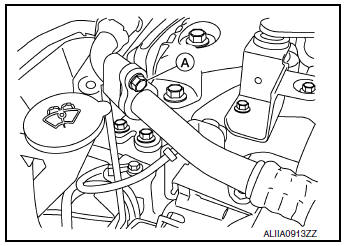

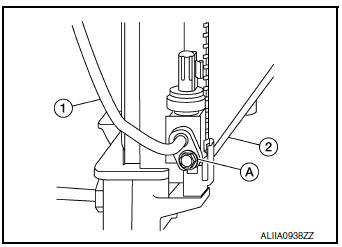

- Remove the bolt (A) that retains the low-pressure and high-pressure pipe to the expansion valve (1).

- Remove low-pressure pipe.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Tighten bolts to specified torque. Refer to HA-32, "Exploded View".

- Do not reuse O-rings.

- Apply A/C oil to new O-rings for installation.

- After charging refrigerant, check for leaks. Refer to HA-21, "Leak Test".

LOW-PRESSURE FLEXIBLE HOSE

LOW-PRESSURE FLEXIBLE HOSE : Removal and Installation

REMOVAL

- Discharge the refrigerant. Refer to HA-23, "Recycle Refrigerant".

- Remove the bolt (A) that retains the low-pressure flexible hose to the low-pressure pipe.

CAUTION: Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

- Remove the nut (A) that retains the low-pressure flexible hose to the compressor.

- Remove the low-pressure flexible hose.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Tighten nut/bolt to specified torque. Refer to HA-32, "Exploded View".

- Do not reuse O-rings.

- Apply A/C oil to new O-rings for installation.

- After charging refrigerant, check for leaks. Refer to HA-21, "Leak Test".

HIGH-PRESSURE PIPE

HIGH-PRESSURE PIPE : Removal and Installation

REMOVAL

- Discharge the refrigerant. Refer to HA-23, "Recycle Refrigerant".

- Remove front bumper fascia. Refer to EXT-17, "Removal and Installation".

- Remove air duct assembly. Refer to EM-24, "Exploded View".

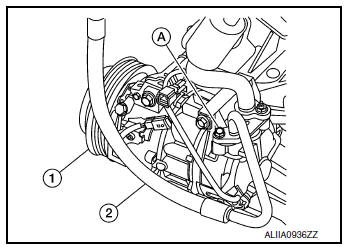

- Remove bolts (A) and upper engine mount (1).

- Release high-pressure pipe (2) from clamp (A).

(1): Low-pressure pipe

(B): Nut

- Remove bolt (A) that retains high-pressure pipe (1) to the condenser

(2).

CAUTION: Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

- Remove the bolt (A) that retains the high-pressure and low-pressure pipe to the expansion valve (1).

- Remove high-pressure pipe.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Tighten bolts to specified torque. Refer to HA-32, "Exploded View".

- Do not reuse O-rings.

- Apply A/C oil to new O-rings for installation.

- After charging the refrigerant, check for leaks. Refer to HA-21, "Leak Test".

HIGH-PRESSURE FLEXIBLE HOSE

HIGH-PRESSURE FLEXIBLE HOSE : Removal and Installation

REMOVAL

- Discharge the refrigerant. Refer to HA-23, "Recycle Refrigerant".

- Remove front bumper fascia. Refer to EXT-17, "Removal and Installation".

- Remove the bolt (A) that retains the high-pressure flexible hose (2) to the condenser (1).

CAUTION: Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

- Remove the bolt (A) that retains the high-pressure flexible hose (2) to the compressor (1).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Tighten bolts to specified torque. Refer to HA-37, "Exploded View".

- Do not reuse O-rings.

- Apply A/C oil to new O-rings for installation.

- After charging the refrigerant, check for leaks. Refer to HA-21, "Leak Test".

Compressor

Compressor

Exploded View

Compressor

Removal and Installation

REMOVAL

Discharge the refrigerant. Refer to HA-23, "Recycle Refrigerant".

Remove the engine under cover. Refer to EX ...

Condenser

Condenser

Exploded View

Air guide (LH)

Condenser upper bracket (LH)

Condenser (includes liquid tank)

Condenser upper bracket (RH)

Air guide (RH)

Refrigerant pressure sensor

C ...

Other materials:

Periodic maintenance

FRONT SUSPENSION ASSEMBLY

Inspection

COMPONENT

Check the conditions (looseness, backlash) of each component. Verify the

component conditions (wear, damage)

are normal.

Ball Joint Axial End Play

Set front wheels in a straight-ahead position.

Move axle side of transverse link, ...

Wheel alignment

Inspection

DESCRIPTION

Measure wheel alignment under unladen conditions.

NOTE:

тАЬUnladen conditionsтАЭ means that fuel, engine coolant, and lubricants are

full. Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY CHECK

Check the following:

&nbs ...

P1212 TCS communication line

Description

This CAN communication line is used to control the smooth engine operation

during the TCS operation. Pulse

signals are exchanged between ECM and тАЬABS actuator and electric unit (control

unit)тАЭ.

Be sure to erase the malfunction information such as DTC not only for тАЬABS

ac ...