Nissan Rogue Service Manual: Brake booster

Inspection

Operation

Depress the brake pedal several times at five second intervals with the engine stopped. Start the engine with the brake pedal fully depressed. Check that the clearance between brake pedal and dash lower panel decreases.

NOTE: A slight impact with a small click may be felt on the pedal when the brake pedal is fully depressed. This is normal brake system operation.

Vacuum Inspection

Idle the engine for one minute to apply vacuum to the brake booster.

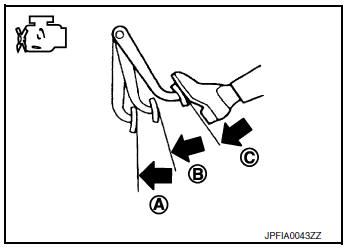

Stop the engine. Depress the brake pedal several times at five second intervals until the accumulated vacuum is released to atmospheric pressure. Check that the clearance between brake pedal and dash lower panel gradually increases (A → B → C) each time the brake pedal is depressed during this operation.

Depress the brake pedal with the engine running. Then stop the engine while holding down the brake pedal. Check that the brake pedal stroke does not change after holding down the brake pedal for 30 seconds or more.

NOTE: A slight impact with a small click may be felt on the pedal when the brake pedal is fully depressed. This is normal brake system operation.

Brake master cylinder

Brake master cylinder

Inspection

Check for brake fluid leakage at the following areas:

Master cylinder mounting face

Reservoir tank mounting face

Brake tube and brake tube connections

Bra ...

Front disc brake

Front disc brake

BRAKE PAD

BRAKE PAD : Inspection

Check brake pad wear thickness from an inspection hole (A) on cylinder

body. Check using a scale if necessary.

Wear thickness : Refer to BR-55, "Front Dis ...

Other materials:

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

...

P0222, P0223 TP sensor

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0222

TP SEN 1/CIRC-B1

(Throttle/pedal position sensor/switch ″B″

circuit low)

An excessively low voltage from the TP sensor 1 is se ...

Moonroof unit assembly

Inspection

WIND DEFLECTOR

Open glass lid fully.

Visually check for proper installation, damaged/deteriorated components,

or foreign objects within mechanism.

Correct as required for smooth operation.

Check for grease at the wind deflector arm (1) and pivot areas. If

necessary, apply ...