Nissan Rogue Service Manual: Power supply and ground circuit

Diagnosis Procedure

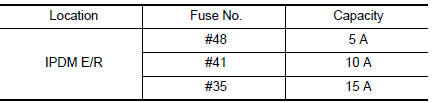

1.CHECK FUSE

Check that the following fuse is not fusing.

Is the fuse fusing? YES >> Replace the fuse after repairing the applicable circuit.

NO >> GO TO 2.

2.CHECK GROUND CONNECTION

- Turn ignition switch OFF.

- Check ground connection E9 or E15. Refer to GI-44, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace ground connection.

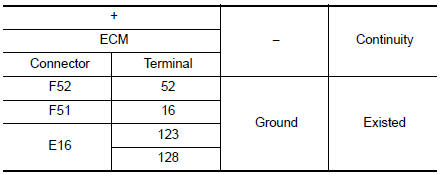

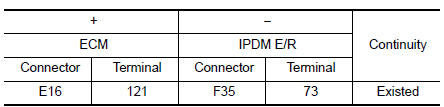

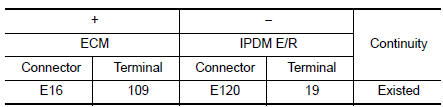

3.CHECK ECM GROUND CIRCUIT

- Disconnect ECM harness connectors.

- Check the continuity between ECM harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

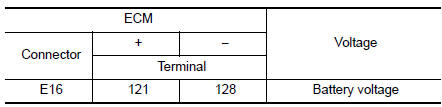

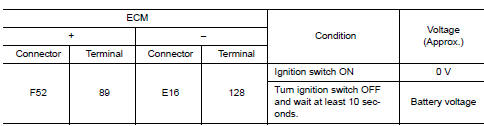

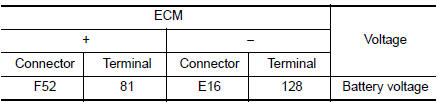

4.CHECK ECM POWER SUPPLY (MAIN)-1

- Reconnect ECM harness connector.

- Turn ignition switch ON.

- Check the voltage between ECM harness connector terminals.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 6.

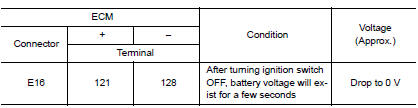

5.CHECK ECM POWER SUPPLY (MAIN)--2

- Turn ignition switch OFF and wait at least 10 seconds.

- Check the voltage between ECM harness connector terminals as per the following.

Is the inspection result normal? YES >> GO TO 9.

NO >> GO TO 7.

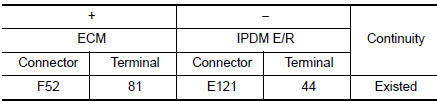

6.CHECK ECM POWER SUPPLY (MAIN) CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connectors.

- Disconnect IPDM E/R harness connector.

- Check the continuity between ECM harness connector and IPDM E/R harness connector.

- Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

7.CHECK ECM RELAY CONTROL SIGNAL

Check the voltage between ECM harness connector terminals as per the following.

Is the inspection result normal? YES >> Check Intermittent Incident. Refer to GI-41, "Intermittent Incident".

NO >> GO TO 8.

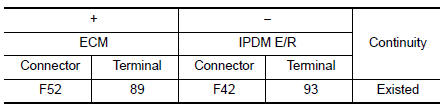

8.CHECK ECM RELAY CONTROL SIGNAL CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Disconnect IPDM E/R harness connector

- Check the continuity between ECM harness connector and IPDM E/R harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> Replace IPDM E/R. Refer to PCS-35, "Removal and Installation".

NO >> Repair or replace error-detected parts.

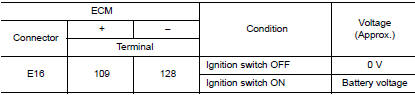

9.CHECK IGNITION SWITCH SIGNAL

- Turn ignition switch ON.

- Check the voltage between ECM harness connector terminals.

Is the inspection result normal? YES >> GO TO 11.

NO >> GO TO 10.

10.CHECK IGNITION SWITCH SIGNAL CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Disconnect IPDM E/R harness connector.

- Check the continuity between ECM harness connector and IPDM E/R harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

11.CHECK ECM POWER SUPPLY (BACK-UP)

Check the voltage between ECM harness connector terminals.

Is the inspection result normal? YES >> Check Intermittent Incident. Refer to GI-41, "Intermittent Incident".

NO >> GO TO 12.

12.CHECK ECM POWER SUPPLY (BACK-UP) CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Disconnect IPDM E/R harness connector.

- Check the continuity between ECM harness connector and IPDM E/R harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

Trouble diagnosis - specification value

Trouble diagnosis - specification value

Description

The specification (SP) value indicates the tolerance of the value that is

displayed in ŌĆ£SPECŌĆØ of ŌĆ£DATA MONITORŌĆØ

mode of CONSULT during normal operation of the Engine Control Sy ...

U0101 CAN comm circuit

U0101 CAN comm circuit

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellen ...

Other materials:

Mirrors

Rearview mirror (if so equipped)

Rearview mirror (if so equipped)

Use the night position 1 to reduce glare from

the headlights of vehicles behind you at night.

Use the day position 2 when driving in daylight

hours.

WARNINGUse the night position only when necessary,

because it r ...

Removal and installation

GENERATOR

Exploded View

REMOVAL

Cylinder head

Generator bracket

Washer

Generator

Water pump

Cylinder block

Removal and Installation

REMOVAL

Disconnect negative terminal from battery. Refer to PG-75,

"Exploded View".

Remove wheel and tire ...

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as ŌĆ£AIR BAGŌĆØ and ŌĆ£SEAT BELT PRE-TENSIONERŌĆØ,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

...