Nissan Rogue Service Manual: P0520 EOP sensor

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition |

| P0520 | EOP SENSOR/SWITCH (Engine oil pressure sensor/switch circuit) | Signal voltage from the EOP sensor remains at more than 5.02 V / less than 0.3 V for 5 seconds or more. |

POSSIBLE CAUSE

- Harness or connectors (EOP sensor circuit is open or shorted.)

- Engine oil level abnormality

- EOP sensor

- Sensor power supply 2 circuit

FAIL-SAFE

Not applicable

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

- Turn ignition switch ON and wait at least 5 seconds.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-358, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK ENGINE OIL

- Turn ignition switch OFF.

- Check engine oil level and pressure. Refer to LU-7, "Inspection".

Is inspection result normal? YES >> GO TO 2.

NO >> Repair or replace error-detected parts.

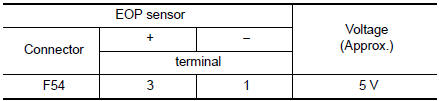

2.CHECK EOP SENSOR POWER SUPPLY-1

- Disconnect EOP sensor connector.

- Turn ignition switch ON.

- Check the voltage between EOP sensor harness connector terminals.

Inspection result normal?

YES >> GO TO 7.

NO >> GO TO 3.

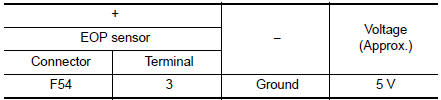

3.CHECK EOP SENSOR POWER SUPPLY-2

Check the voltage between EOP sensor harness connector and the ground.

Is inspection result normal? YES >> GO TO 5.

NO >> GO TO 4.

4.CHECK SENSOR POWER SUPPLY 2 CIRCUIT

Perform EC-484, "Diagnosis Procedure".

Is inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

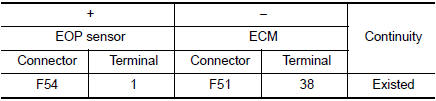

5.CHECK EOP SENSOR GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between EOP sensor harness connector and ECM harness connector.

- Also check harness for short to power.

Is inspection result normal? YES >> GO TO 6.

NO >> Repair or replace error-detected parts.

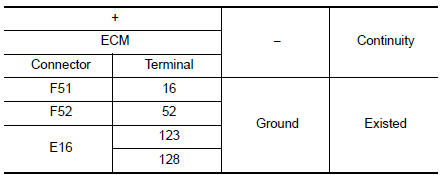

6.CHECK ECM GROUND CIRCUIT

Check the continuity between ECM harness connector and ground.

Is inspection result normal? YES >> GO TO 9.

NO >> Repair or replace error-detected parts.

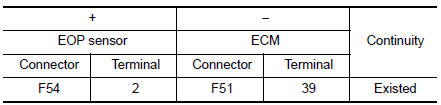

7.CHECK EOP SENSOR SIGNAL CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between EOP sensor harness connector and ECM harness connector.

- Also check harness for short to ground and to power.

Is inspection result normal? YES >> GO TO 8.

NO >> Repair or replace error-detected parts.

8.CHECK EOP SENSOR

Refer to EC-360, "Component Inspection".

Is inspection result normal? YES >> GO TO 9.

NO >> Repair or replace error-detected parts.

9.CHECK INTERMITTENT INCIDENT

Refer to GI-41, "Intermittent Incident".

>> INSPECTION END

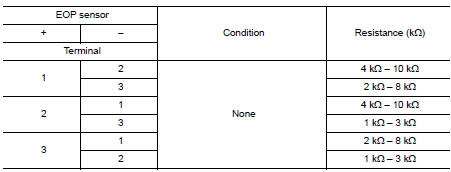

Component Inspection

1.CHECK EOP SENSOR

- Turn ignition switch OFF.

- Disconnect EOP sensor harness connector.

- Check resistance between EOP sensor connector terminals.

Is the inspection result normal? YES >> INSPECTION END.

NO >> Replace EOP sensor. Refer to EC-14, "Component Parts Location".

P050A, P050B, P050E cold start control

P050A, P050B, P050E cold start control

Description

ECM controls ignition timing and engine idle speed when engine is started

with pre-warming up condition.

This control promotes the activation of three way catalyst by heating the

c ...

P0524 engine oil pressure

P0524 engine oil pressure

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0524

ENGINE OIL PRESSURE

(Engine oil pressure too ...

Other materials:

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

...

U0140 lost communication (BCM)

DTC Description

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

U0140

LOST COMM (BCM)

(Lost Communication With Body Control Module)

When the ignition switch is ON, TCM is unable to receive the CAN

communications ...

Vehicle identification

Vehicle identification number (VIN) plate

The vehicle identification number (VIN) plate is

located as shown. This number is the identification

for your vehicle and is used in the vehicle

registration.

The VIN number is also available through the

center display screen. For additional inf ...