Nissan Rogue Service Manual: P0222, P0223 TP sensor

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition |

| P0222 | TP SEN 1/CIRC-B1 (Throttle/pedal position sensor/switch ″B″ circuit low) | An excessively low voltage from the TP sensor 1 is sent to ECM. |

| P0223 | TP SEN 1/CIRC-B1 (Throttle/pedal position sensor/switch ″B″ circuit high) | An excessively high voltage from the TP sensor 1 is sent to ECM. |

POSSIBLE CAUSE

- Harness or connectors (TP sensor 1 circuit is open or shorted.)

- Electric throttle control actuator (TP sensor 1)

FAIL-SAFE

- The ECM controls the electric throttle control actuator in regulating the throttle opening in order for the idle position to be within +10 degrees.

- The ECM regulates the opening speed of the throttle valve to be slower than the normal condition. So, the acceleration will be poor.

DTC CONFIRMATION PROCEDURE

1.CHECK DTC PRIORITY

If DTC P0222 or P0223 is displayed with DTC P0643, first perform the trouble diagnosis for DTC P0643.

Is applicable DTC detected? YES >> Perform diagnosis of applicable. Refer to EC-379, "DTC Description".

NO >> GO TO 2.

2.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION: Before performing the following procedure, confirm that battery voltage is more than 8 V at idle.

>> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE

- Start engine and let it idle for 1 second.

- Check DTC.

Is DTC detected? YES >> Proceed to EC-284, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK DTC PRIORITY

If DTC P0222 or P0223 is displayed with DTC P0643, first perform the trouble diagnosis for DTC P0643.

Is applicable DTC detected? YES >> Perform diagnosis of applicable. Refer to EC-379, "DTC Description".

NO >> GO TO 2.

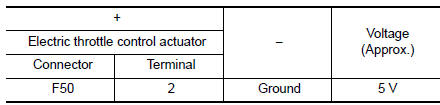

2.CHECK THROTTLE POSITION SENSOR 1 POWER SUPPLY

- Turn ignition switch OFF.

- Disconnect electric throttle control actuator harness connector.

- Turn ignition switch ON.

- Check the voltage between electric throttle control actuator harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

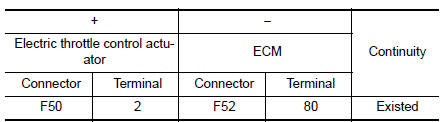

3.CHECK THROTTLE POSITION SENSOR 1 POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between electric throttle control actuator harness connector and ECM harness connector.

- Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

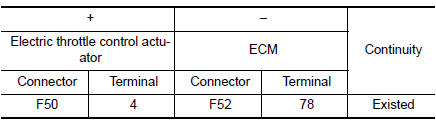

4.CHECK THROTTLE POSITION SENSOR 1 GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between electric throttle control actuator harness connector and ECM harness connector.

- Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

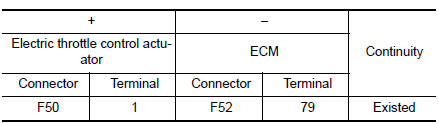

5.CHECK THROTTLE POSITION SENSOR 1 INPUT SIGNAL CIRCUIT

- Check the continuity between electric throttle control actuator harness connector and ECM harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

6.CHECK THROTTLE POSITION SENSOR

Check the throttle position sensor. Refer to EC-286, "Component Inspection".

Is the inspection result normal? YES >> GO TO 7.

NO >> Replace electric throttle control actuator. Refer to EM-26, "Removal and Installation".

7.CHECK INTERMITTENT INCIDENT

Refer to GI-41, "Intermittent Incident".

>> INSPECTION END

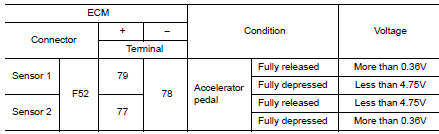

Component Inspection

1.CHECK THROTTLE POSITION SENSOR

- Turn ignition switch OFF.

- Reconnect all harness connectors disconnected.

- Perform “ Throttle Valve Closed Position Learning”. Refer to EC-140, "Work Procedure".

- Turn ignition switch ON.

- Set selector lever to D position.

- Check the voltage between ECM harness connector terminals as per the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace electric throttle control actuator. Refer to EM-26, "Removal and Installation".

P0197, P0198 EOT sensor

P0197, P0198 EOT sensor

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0197

EOT SEN/CIRC

(Engine oil temperature sensor ...

P0300, P0301, P0302, P0303, P0304 misfire

P0300, P0301, P0302, P0303, P0304 misfire

DTC Description

DTC DETECTION LOGIC

When a misfire occurs, engine speed will fluctuate. If the engine speed

fluctuates enough to cause the crankshaft

position (CKP) sensor (POS) signal to vary, E ...

Other materials:

Precautions

Description]

Observe the following precautions to ensure safe and proper servicing. These

precautions are not

described in each individual section.

Precaution for supplemental restraint system

(srs) "air bag" and "seat belt pre-tensioner"

The Supplemental Restraint System ...

Preparation

Special Service Tools

The actual shape of the tools may differ from those illustrated here.

Tool number

(TechMate No.)

Tool name

Description

—

(J-46534)

Trim Tool Set

Removing trim components

...

C1155 brake fluid level switch

DTC Logic

DTC DETECTION LOGIC

DTC

Display Item

Malfunction detected condition

Possible causes

C1155

BR FLUID LEVEL LOW

When brake fluid level low signal is detected

Harness or connector

ABS actuator and electric unit

(control unit)

...