Nissan Rogue (T33) 2021-Present Service Manual: P015a A/f Sensor 1

DTC Description

DTC DETECTION LOGIC

To judge malfunctions, this diagnosis measures response time of the A/F signal computed by ECM from the A/F sensor 1 signal. The time is compensated by engine operating (speed and load), fuel feedback control constant, and the A/F sensor 1 temperature index. Judgment is based on whether the compensated time (the A/F signal cycling time index) is inordinately long or not.

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | ||

| P015A | 00 |

A/F SENSOR1 (B1) (O2 sensor delayed response - rich to lean bank 1 sensor 1) |

Diagnosis condition | — |

| Signal (terminal) | A/F sensor 1 signal | |||

| Threshold | The response time of a A/F sensor 1 signal delays more than the specified time computed by ECM | |||

| Diagnosis delay time | — | |||

POSSIBLE CAUSE

-

Harness or connectors (The A/F sensor 1 circuit is open or shorted.)

-

A/F sensor 1

FAIL-SAFE

Not applicable

DTC Confirmation Procedure

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Turn ignition switch ON.

-

Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 11 V at idle.

Do you have CONSULT?

YES>>GO TO 2.

NO>>GO TO 6.

PERFORM DTC CONFIRMATION PROCEDURE-1

With CONSULT

With CONSULT

-

Start engine and warm it up to normal operating temperature.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Turn ignition switch ON.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1minute under no load.

-

Let engine idle for 1 minute.

-

Increase the engine speed up to about 3,600 rpm and keep it for 10 seconds.

-

Fully release accelerator pedal and then let engine idle for about 1 minute.

-

Check the items status of “DATA MONITOR” as follows.

NOTE:

NOTE:

If “PRSNT” changed to “ABSNT”, refer to Component Function Check.

Data monitor item Status A/F SEN1 DIAG3 (B1) PRSNT

Is “PRSNT” displayed on CONSULT screen?

YES>>GO TO 4.

NO>>GO TO 3.

PERFORM DTC CONFIRMATION PROCEDURE-2

With CONSULT

With CONSULT

Perform DTC confirmation procedure-1 again.

Is “PRSNT” displayed on CONSULT screen?

YES>>GO TO 4.

NO>>Refer to Component Function Check.

PERFORM DTC CONFIRMATION PROCEDURE-2

With CONSULT

With CONSULT

-

Wait for about 20 seconds at idle.

-

Check the items status of “DATA MONITOR” as follows.

NOTE:

NOTE:

If “CMPLT” changed to “INCMP”, refer to Component Function Check.

Data monitor item Status A/F SEN1 DIAG1 (B1) CMPLT A/F SEN1 DIAG2 (B1)

Is “CMPLT” displayed on CONSULT screen?

YES>>GO TO 5.

NO>>Refer to Component Function Check.

PERFORM SELF-DIAGNOSIS

With CONSULT

With CONSULT

Check the “SELF-DIAG RESULT”.

Is any DTC detected?

YES>>Proceed to DTC Diagnosis Procedure.

NO>>INSPECTION END

CHECK AIR-FUEL RATIO SELF-LEARNING VALUE

With GST

With GST

-

Start engine and warm it up to normal operating temperature.

-

Select Service $01 with GST.

-

Calculate the total value of “Short term fuel trim” and “Long term fuel trim” indications.

Is the total percentage within ±15%?

YES>>GO TO 8.

NO>>GO TO 7.

DETECT MALFUNCTIONING PART

Check the following.

-

Intake air leaks

-

Exhaust gas leaks

-

Incorrect fuel pressure

-

Lack of fuel

-

Fuel injector

-

Incorrect PCV hose connection

-

PCV valve

-

Mass air flow sensor

>>

Repair or replace malfunctioning part.

PERFORM DTC CONFIRMATION PROCEDURE

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Turn ignition switch ON.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

-

Let engine idle for 1 minute.

-

Increase the engine speed up to about 3,600 rpm and keep it for 10 seconds.

-

Fully release accelerator pedal and then let engine idle for about 1 minute.

-

Check 1st trip DTC.

Is 1st trip DTC detected?

YES>>Proceed to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

RETIGHTEN A/F SENSOR 1

Loosen and retighten the A/F sensor 1. Refer to Exploded View.

>>

GO TO 2.

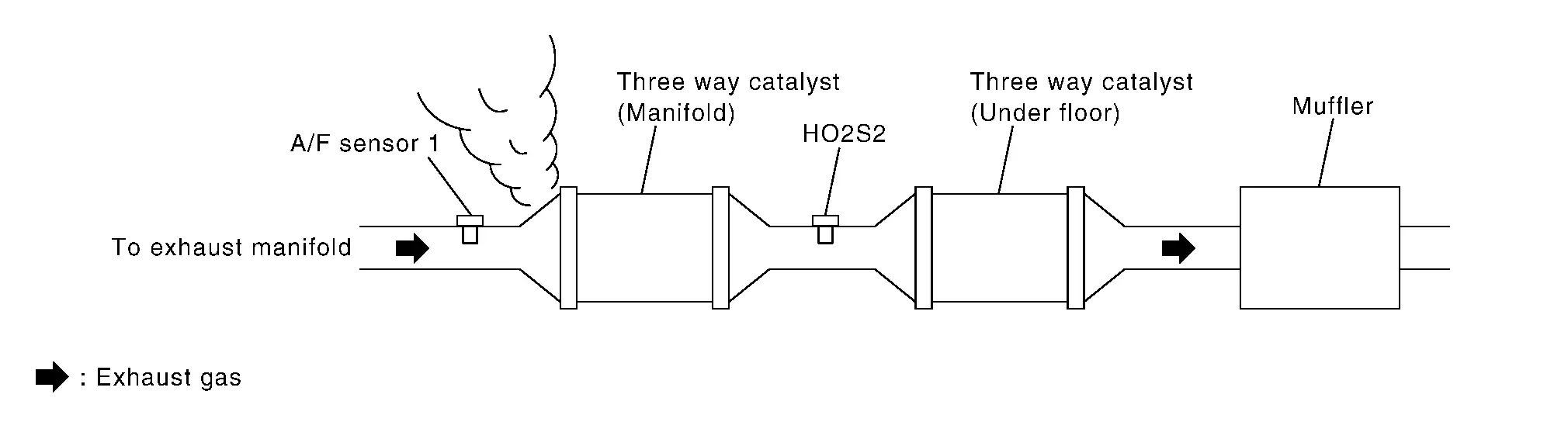

CHECK EXHAUST GAS LEAK

-

Start engine and run it at idle.

-

Listen for an exhaust gas leak before three way catalyst (manifold).

Is exhaust gas leak detected?

YES>>Repair or replace.

NO>>GO TO 3.

CHECK FOR INTAKE AIR LEAK

Listen for an intake air leak after the mass air flow sensor.

Is intake air leak detected?

YES>>Repair or replace.

NO>>GO TO 4.

CLEAR THE MIXTURE RATIO SELF-LEARNING VALUE

-

Clear the mixture ratio self-learning value. Refer to Description.

-

Run engine for at least 10 minutes at idle speed.

Is the 1st trip DTC P0171 or P172 detected? Is it difficult to start engine?

YES>>Perform trouble diagnosis for DTC P0171 or P0172. Refer to DTC Description or DTC Description.

NO>>GO TO 5.

CHECK AIR FUEL RATIO (A/F) SENSOR 1 POWER SUPPLY CIRCUIT

-

Disconnect A/F sensor 1 harness connector.

-

Turn ignition switch ON.

-

Check the voltage between A/F sensor 1 harness connector and ground.

+ – Voltage A/F sensor 1 Connector Terminal F18 4 Ground Battery voltage

Is the inspection result normal?

YES>>GO TO 6.

NO>>Repair or replace error-detected parts.

CHECK A/F SENSOR 1 INPUT SIGNAL CIRCUIT

-

Turn ignition switch OFF.

-

Disconnect ECM harness connector.

-

Check the continuity between A/F sensor 1 harness connector and ECM harness connector.

+ – Continuity A/F sensor 1 ECM Connector Terminal Connector Terminal F18 1 F72 56 Existed 2 60 -

Check the continuity between A/F sensor 1 harness connector and ground, or ECM harness connector and ground.

+ – Continuity A/F sensor 1 Connector Terminal F18 1 Ground Not existed 2 + – Continuity ECM Connector Terminal F72 56 Ground Not existed 60 -

Also check harness for short to power.

Is the inspection result normal?

YES>>GO TO 7.

NO>>Repair or replace error-detected parts.

CHECK AIR FUEL RATIO (A/F) SENSOR 1 HEATER

Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 8.

NO>>GO TO 11.

CHECK MASS AIR FLOW SENSOR

Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 9.

NO>>Replace mass air flow sensor. Refer to Exploded View.

CHECK PCV VALVE

Refer to POSITIVE CRANKCASE VENTILATION : Periodic Maintenance.

Is the inspection result normal?

YES>>GO TO 10.

NO>>Repair or replace PCV valve. Refer to Exploded View.

CHECK INTERMITTENT INCIDENT

Refer to Intermittent Incident.

Is the inspection result normal?

YES>>GO TO 11.

NO>>Repair or replace.

REPLACE AIR FUEL RATIO (A/F) SENSOR 1

Replace air fuel ratio (A/F) sensor 1. Refer to Exploded View.

>>

INSPECTION END

Other materials:

Dtc/circuit Diagnosis. B0028-1a Side A/b Module Rh

DTC Description

DTC DETECTION LOGIC DTC No.

CONSULT screen items

(Trouble diagnosis content) DTC Detection Condition

B0028-1A

SIDE A/B MODULE RH

(Right Side Airbag Deployment Control)

Diagnosis condition

When ignition switch is ON.

Signal (terminal)

Front side air bag modu ...

Dtc/circuit Diagnosis. B1029-09 Front Seat Belt Pre-Tensioner Lh

DTC Description

DTC DETECTION LOGIC DTC No.

CONSULT screen items

(Trouble diagnosis content) DTC Detection Condition

B1029-09

Front seat belt pre-tensioner LH

(Front seat belt pre-tensioner left hand)

Diagnosis condition

When ignition switch is ON.

Signal (terminal)

Front ...

Dtc/circuit Diagnosis. C161b-86 Abs System

DTC Description

DTC DETECTION LOGIC DTC No.

CONSULT screen terms

(Trouble diagnosis content) DTC detection condition

C161B

86

ABS system

(Anti-lock braking system )

Diagnosis condition

When ignition switch is ON.

Signal (terminal)

CAN communication signal

Threshold ...