Nissan Rogue Service Manual: Front disc brake

BRAKE CALIPER ASSEMBLY (1 PISTON TYPE)

BRAKE CALIPER ASSEMBLY (1 PISTON TYPE) : Exploded View

- Torque member

- Bushing

- Piston boot

- Slide pin boot

- Slide pin

- Piston

- Piston seal

- Brake caliper body

- Bleeder cap

- Brake hose

- Copper sealing washers

- Inner shim cover

- Inner shim

- Inner pad

- Pad retainer

- Anti-rattle clip

- Outer pad

- Outer shim

- Outer shim cover

- Molykote AS-880N

- Niglube Rx-2

: Apply brake fluid.

: Apply brake fluid.

BRAKE CALIPER ASSEMBLY (1 PISTON TYPE) : Disassembly and Assembly

DISASSEMBLY

- Remove the brake caliper from the vehicle. Refer to BR-35, "BRAKE CALIPER ASSEMBLY (1 PISTON TYPE) : Removal and Installation".

- Remove sliding pins and sliding pin boots from torque member.

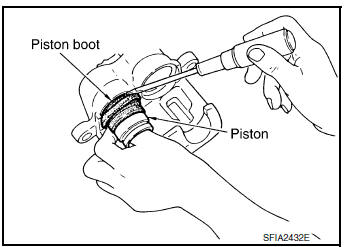

- Place a wooden block in brake caliper body and blow air from

union bolt hole to remove piston and piston boots.

WARNING: Do not get fingers caught between piston and brake caliper body.

CAUTION: Do not reuse piston boots.

- Remove piston seals from brake caliper body using suitable tool.

CAUTION:

- Do not damage cylinder inner wall.

- Do not reuse piston seals.

- Remove bleeder valve and cap.

INSPECTION AFTER DISASSEMBLY

Brake Caliper Body

Check the inner wall of the brake caliper body for rust, wear, cracks or damage. Replace the brake caliper body if any abnormal condition is detected.

CAUTION: Always clean with new brake fluid. Do not clean with mineral oil such as gasoline and light oil.

Torque Member

Check the torque member for rust, wear, cracks or damage. Replace the torque member if any abnormal condition is detected.

Piston Check the surface of the piston for rust, wear, cracks or damage. Replace the piston if any abnormal condition is detected.

CAUTION: Piston sliding surface is plated. Do not polish with sandpaper.

Sliding Pin and Sliding Pin Boot

Check the sliding pins and sliding pin boots for rust, wear, cracks or damage. Replace the parts if any abnormal condition is detected.

ASSEMBLY

- Install bleeder valve and cap.

- Apply rubber grease to each piston seal (1), and install them to the brake caliper body.

CAUTION: Do not reuse piston seal.

- Apply rubber grease to the piston boots. Cover each piston end

with a piston boot, and then install cylinder side lip on piston

boot securely into a groove on brake caliper body.

CAUTION: Do not reuse piston boots.

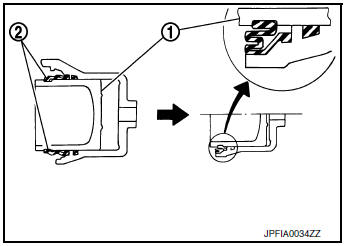

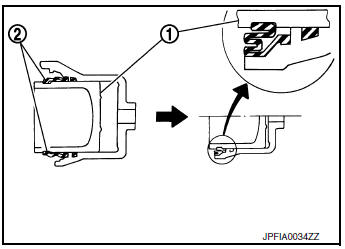

- Apply brake fluid to each piston (1). Push each piston into cylinder

body by hand and push piston boot (2) piston-side lip into

the piston groove.

CAUTION: Press the piston evenly and vary the pressing point to prevent cylinder inner wall from being rubbed.

- Apply rubber grease to bushing; install bushing to sliding pin.

- Apply rubber grease to sliding pins and sliding pin boots, install sliding pins and sliding pin boots to torque member.

- Install the brake caliper to the vehicle. Refer to BR-35, "BRAKE CALIPER ASSEMBLY (1 PISTON TYPE) : Removal and Installation".

INSPECTION AFTER INSTALLATION

- Check the drag of front disc brake. If any drag is found, follow the procedure described below.

- Remove brake pads.

- Using a suitable tool, press the piston into the brake caliper

body.

CAUTION: Do not damage the piston boots.

- Install brake pads.

- Depress the brake pedal several times.

- Check the drag of front disc brake again. If any drag is found, disassemble the brake caliper body.

- Burnish contact surfaces after refinishing or replacing disc

rotors or if a soft pedal occurs at very low mileage.

Refer to BR-18, "Brake Burnishing".

BRAKE CALIPER ASSEMBLY (2 PISTON TYPE)

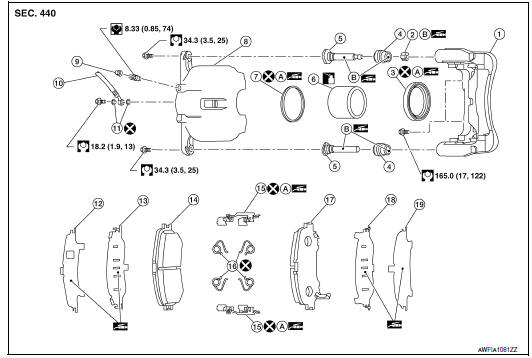

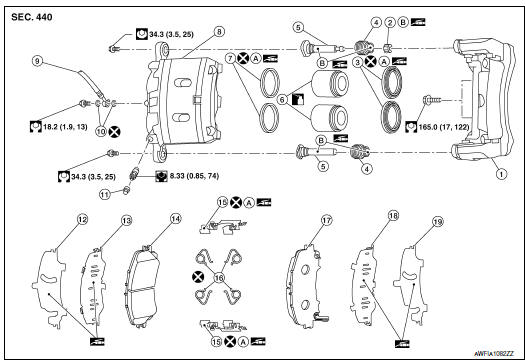

BRAKE CALIPER ASSEMBLY (2 PISTON TYPE) : Exploded View

- Torque member

- Bushing

- Piston boot

- Slide pin boot

- Slide pin

- Piston

- Piston seal

- Brake caliper body

- Bleeder cap

- Brake hose

- Copper sealing washers

- Inner shim cover

- Inner shim

- Inner pad

- Pad retainer

- Anti-rattle clip

- Outer pad

- Outer shim

- Outer shim cover

- Molykote AS-880N

- Niglube Rx-2

: Apply brake fluid.

: Apply brake fluid.

BRAKE CALIPER ASSEMBLY (2 PISTON TYPE) : Disassembly and Assembly

DISASSEMBLY

- Remove the brake caliper from the vehicle. Refer to BR-39, "BRAKE CALIPER ASSEMBLY (2 PISTON TYPE) : Removal and Installation".

- Remove sliding pins and sliding pin boots from torque member.

- Place a wooden block in brake caliper body and blow air from

union bolt hole to remove pistons and piston boots.

WARNING: Do not get fingers caught between pistons and brake caliper body.

CAUTION: Do not reuse piston boots.

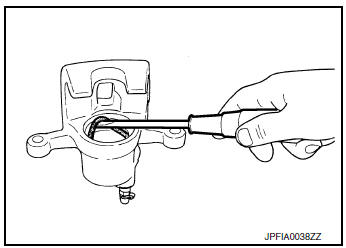

- Remove piston seals from brake caliper body using suitable tool.

CAUTION:

- Do not damage cylinder inner wall.

- Do not reuse piston seals.

- Remove bleeder valve and cap.

INSPECTION AFTER DISASSEMBLY

Brake Caliper Body

Check the inner wall of the brake caliper body for rust, wear, cracks or damage. Replace the brake caliper body if any abnormal condition is detected.

CAUTION: Always clean with new brake fluid. Do not clean with mineral oil such as gasoline and light oil.

Torque Member

Check the torque member for rust, wear, cracks or damage. Replace the torque member if any abnormal condition is detected.

Piston

Check the surface of the piston for rust, wear, cracks or damage. Replace the piston if any abnormal condition is detected.

CAUTION: Piston sliding surface is plated. Do not polish with sandpaper.

Sliding Pin and Sliding Pin Boot

Check the sliding pins and sliding pin boots for rust, wear, cracks or damage. Replace the parts if any abnormal condition is detected.

ASSEMBLY

- Install bleeder valve and cap.

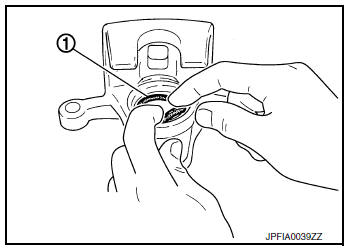

- Apply rubber grease to each piston seal (1), and install them to

the brake caliper body.

CAUTION: Do not reuse piston seal.

- Apply rubber grease to the piston boots. Cover each piston end

with a piston boot, and then install cylinder side lip on piston

boot securely into a groove on brake caliper body.

CAUTION: Do not reuse piston boots.

- Apply brake fluid to each piston (1). Push each piston into cylinder

body by hand and push piston boot (2) piston-side lip into

the piston groove.

CAUTION: Press the piston evenly and vary the pressing point to prevent cylinder inner wall from being rubbed.

- Apply rubber grease to bushing; install bushing to sliding pin.

- Apply rubber grease to sliding pins and sliding pin boots, install sliding pins and sliding pin boots to torque member.

- Install the brake caliper to the vehicle. Refer to BR-39, "BRAKE CALIPER ASSEMBLY (2 PISTON TYPE) : Removal and Installation".

INSPECTION AFTER INSTALLATION

- Check the drag of front disc brake. If any drag is found, follow the procedure described below.

- Remove brake pads.

- Using a suitable tool, press the pistons into the brake caliper

body.

CAUTION: Do not damage the piston boots.

- Install brake pads.

- Depress the brake pedal several times

- Check the drag of front disc brake again. If any drag is found, disassemble the brake caliper body.

- Burnish contact surfaces after refinishing or replacing disc

rotors or if a soft pedal occurs at very low mileage.

Refer to BR-18, "Brake Burnishing".

Rear disc brake

Rear disc brake

Exploded View

Sliding pin bolt

Sliding pin bolt bushing

Cap

Bleeder valve

Brake caliper body

Piston seal

Piston

Piston boot

Sliding pin boot

&nb ...

Other materials:

Unit disassembly and assembly

CENTER CONSOLE ASSEMBLY

Exploded View

Center console cup holder (without

heated seats)

Coin tray insert

Center console cup holder (with

heated seats)

Front heated seat switch (RH)

Front heated seat switch (LH)

Shift selector finisher

Shift selector ...

Air conditioner system refrigerant and oil recommendations

The air conditioner system in your NISSAN

vehicle must be charged with the refrigerant

HFC-134a (R-134a) and NISSAN A/C

system oil Type ND-OIL8 or the exact

equivalents.

CAUTIONThe use of any other refrigerant or oil will

cause severe damage to the air conditioning

system and will ...

Power window and door lock/unlock switch RH

Removal and Installation

REMOVAL

Remove the front door pull handle bracket (RH). Refer to INT-15,

"Removal and Installation".

Release pawls using a suitable tool (A) and remove front door

power window and door lock/unlock switch finisher (RH) (1).

: Pawl

D ...