Nissan Rogue Service Manual: Corrosion protection

Description

To provide improved corrosion prevention, the following anti-corrosive measures have been implemented in NISSAN production plants. When repairing or replacing body panels, it is necessary to use the same anti-corrosive measures.

ANTI-CORROSIVE PRECOATED STEEL (GALVANNEALED STEEL)

To improve repairability and corrosion resistance, a new type of anticorrosive precoated steel sheet has been adopted replacing conventional zinc-coated steel sheet.

Galvannealed steel is electroplated and heated to form Zinc-iron alloy, which provides excellent and long term corrosion resistance with cationic electrodeposition primer.

NISSAN Genuine Service Parts are fabricated from galvannealed steel. Therefore, it is recommended that GENUINE NISSAN PARTS or equivalent be used for panel replacement to maintain the anti-corrosive performance built into the vehicle at the factory.

PHOSPHATE COATING TREATMENT AND CATIONIC ELECTRODEPOSITION PRIMER

A phosphate coating treatment and a cationic electrodeposition primer, which provide excellent corrosion protection, are employed on all body components.

CAUTION: Confine paint removal during welding operations to an absolute minimum.

NISSAN Genuine Service Parts are also treated in the same manner. Therefore, it is recommended that GENUINE NISSAN PARTS or an equivalent be used for panel replacement to maintain anti-corrosive performance built into the vehicle at the factory.

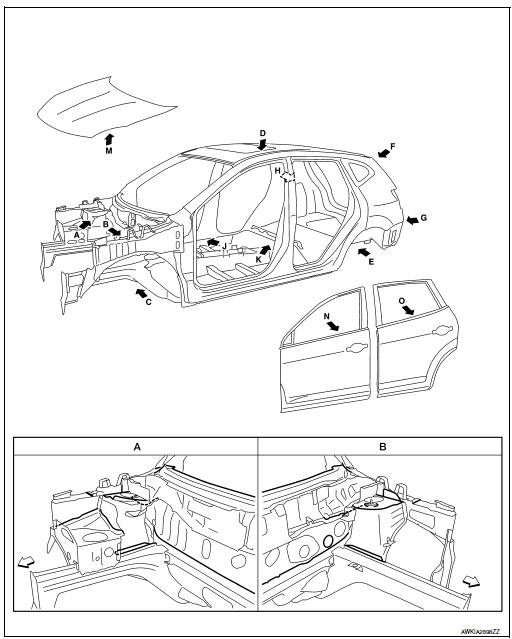

Anti-corrosive Wax

To improve corrosion resistance, anti-corrosive wax is applied inside the body sill and inside other closed sections.

Accordingly, when replacing these parts, be sure to apply anti-corrosive wax to the appropriate areas of the new parts. Select an excellent anti-corrosive wax which will penetrate after application and has a long shelf life.

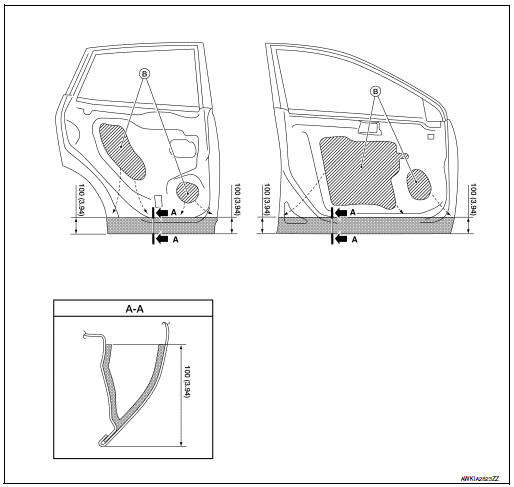

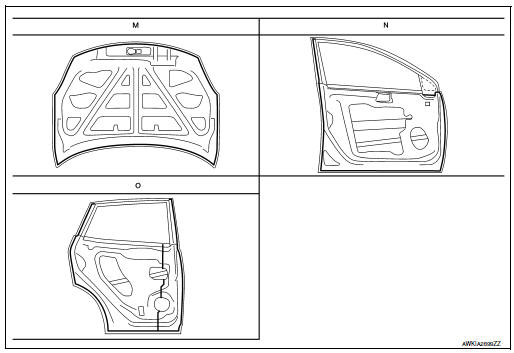

DOOR

- Nozzle insert hole

Anti-corrosive wax coated

portions

Anti-corrosive wax coated

portions

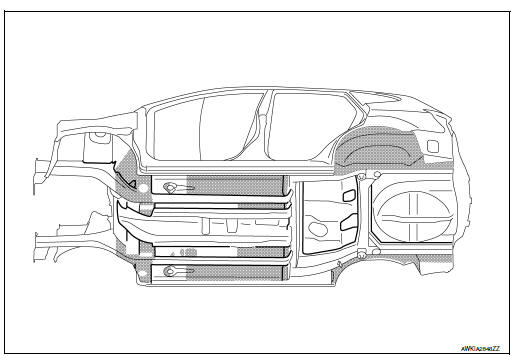

Undercoating

The underside of the floor and wheelhouse are undercoated to prevent rust, vibration, noise and stone chipping.

Therefore, when such a panel is replaced or repaired, apply undercoating to that part. Use an undercoating which is rust preventive, soundproof, vibration-proof, shock-resistant, adhesive, and durable

PRECAUTIONS IN UNDERCOATING

- Never apply undercoating to any place unless specified (such as the areas above the muffler and three way catalyst which are subjected to heat).

- Never undercoat the exhaust pipe or other parts which become hot.

- Never undercoat rotating parts.

- Apply bitumen wax after applying undercoating.

- After putting seal on the vehicle, put undercoating on it.

Undercoated portions (for all

destination)

Undercoated portions (for all

destination)

Sealed portions

Sealed portions

Stone Guard Coat

To prevent damage caused by stones, the lower outer body panel (fender, door, etc.) have an additional layer of Stone Guard Coating over the ED primer coating. When replacing or repairing these panels, apply Stone Guard coating to the same portions as before. Use a coating which is rust preventive, durable, shock-resistant and has a long shelf life.

- Outer sill portion

- Door outer portion

Stone guard coated portions

Stone guard coated portions

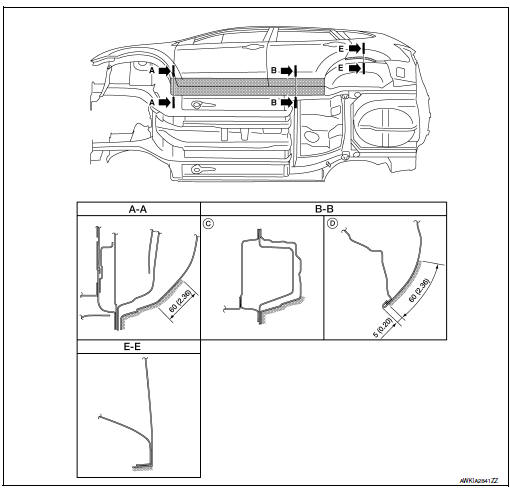

Body Sealing

The following figure shows the areas which are sealed at the factory. Sealant which has been applied to these areas should be smooth and free from cuts or gaps. Care should be taken not to apply an excess amount of sealant and not to allow other unaffected parts to come into contact with the sealant.

Front

Front

Sealed portions

Sealed portions

Front

Front

Sealed portions

Sealed portions

Front

Front

Sealed portions

Sealed portions

Body construction

Body construction

Body Construction

Outer body side

Outer front pillar reinforcement

Upper inner front pillar

Rear hoodledge reinforcement

Side dash

Inner front pillar reinforcement

Lower ...

Other materials:

Wiring diagram

DRIVER ASSISTANCE SYSTEMS

Wiring Diagram

...

Starting the engine (models with NISSAN

Intelligent Key® system)

Apply the parking brake.

Move the shift lever to P (Park) or N (Neutral).

P (Park) is recommended.

The starter is designed not to operate if

the shift lever is in any of the driving

positions.

Push the ignition switch to the ON position.

Depress the brake pedal and pus ...

Third row seats

Exploded View

Seatback board (RH)

Seatback trim (RH)

Seatback pad (RH)

Seat cushion trim (RH)

Seat cushion pad (RH)

Seat cushion silencer (LH/RH)

Seat hinge finisher (RH)

Gas stay

Bolt cover (RH)

Seat belt buckle (RH)

Seat belt buckle (LH)

Bolt ...