Nissan Rogue Service Manual: C1115 ABS sensor [abnormal signal]

DTC Logic

DTC DETECTION LOGIC

| DTC | Display Item | Malfunction detected condition | Possible causes |

| C1115 | ABS SENSOR [ABNORMAL SIGNAL] | When difference in wheel speed between any wheel and others is detected while the vehicle is driven because of installation of tires other than specified. |

|

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT

With CONSULT.

With CONSULT.

- Start engine and drive vehicle at approximately 30 km/h (19 MPH) or more for approximately 1 minute.

- Perform self-diagnostic result.

Is DTC C1115 detected? YES >> Proceed to diagnosis procedure. Refer to BRC-85, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to BRC-57, "Wiring Diagram".

CAUTION: Do not check between wheel sensor terminals.

1.CONNECTOR INSPECTION

- Disconnect ABS actuator and electric unit (control unit) connector E125 and wheel sensor connector of wheel with DTC.

- Check terminals for deformation, disconnection, looseness or damage.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace as necessary.

2.CHECK WHEEL SENSOR OUTPUT SIGNAL

- Connect ABS active wheel sensor tester (J-45741) to wheel sensor using appropriate adapter.

- Turn on the ABS active wheel sensor tester power switch.

NOTE: The green POWER indicator should illuminate. If the POWER indicator does not illuminate, replace the battery in the ABS active wheel sensor tester before proceeding.

- Spin the wheel of the vehicle by hand and observe the red SENSOR

indicator on the ABS active wheel

sensor tester. The red SENSOR indicator should flash on and off to indicate

an output signal.

NOTE: If the red SENSOR indicator illuminates but does not flash, reverse the polarity of the tester leads and retest.

Does the ABS active wheel sensor tester detect a signal? YES >> GO TO 3.

NO >> Replace the wheel sensor. Refer to BRC-132, "FRONT WHEEL SENSOR : Removal and Installation" or BRC-134, "REAR WHEEL SENSOR : Removal and Installation".

3.CHECK TIRES

Check the inflation pressure, wear and size of each tire.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Adjust tire pressure, or replace tire(s).

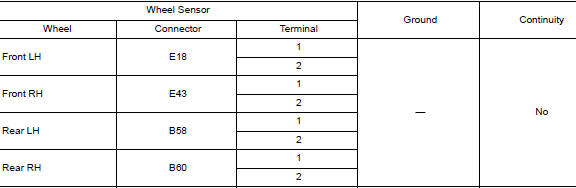

4.CHECK WIRING HARNESS FOR SHORT CIRCUIT

Check continuity between wheel sensor connector terminals and ground of wheel with DTC.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair the circuit.

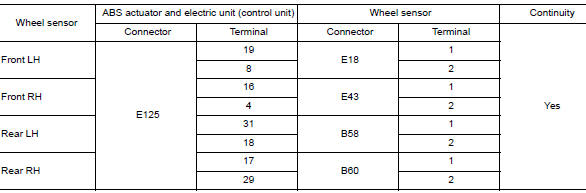

5.CHECK WIRING HARNESS FOR OPEN CIRCUIT

Check continuity between ABS actuator and electric unit (control unit) connector E125 and wheel sensor connector of wheel with DTC.

Is the inspection result normal? YES >> Replace the ABS actuator and electric unit (control unit). Refer to BRC-136, "Removal and Installation".

NO >> Repair the circuit.

C1113, C1145, C1146 yaw rate/side/decel G sensor

C1113, C1145, C1146 yaw rate/side/decel G sensor

DTC

Display Item

Malfunction detected condition

Possible causes

C1113

G SENSOR

When a malfunction is detected in longitudinal G sensor

signal.

Harness or ...

C1120, C1122, C1124, C1126 ABS in valve system

C1120, C1122, C1124, C1126 ABS in valve system

DTC Logic

DTC DETECTION LOGIC

DTC

Display Item

Malfunction detected condition

Possible causes

C1120

FR LH IN ABS SOL

When a malfunction is detected in front LH ABS IN

...

Other materials:

Symptom diagnosis

INTERIOR LIGHTING SYSTEM SYMPTOMS

Symptom Table

CAUTION:

Perform the self-diagnosis with CONSULT before the symptom diagnosis. Perform

the trouble diagnosis

if any DTC is detected.

Symptom

Possible cause

Inspection item

All the following lamps do not turn ON. ...

Does not operate

Description

VDC function, TCS function, ABS function, EBD function, Brake limited slip

differential (BLSD) function, Brake

assist function, hill start assist function or Brake force distribution function

does not operate.

Diagnosis Procedure

CAUTION:

VDC function, TCS function, ABS ...

TPMS

Symptom Table

LOW TIRE PRESSURE WARNING LAMP SYMPTOM CHART

Diagnosis

items

Symptom

(Power switch ON)

Low tire pressure warning lamp

Cause

Action

Low tire pressure

warning

lamp

The low tire pressure

warning lamp

illuminates for 1

second, then turn ...