Nissan Rogue Service Manual: Brake piping

FRONT

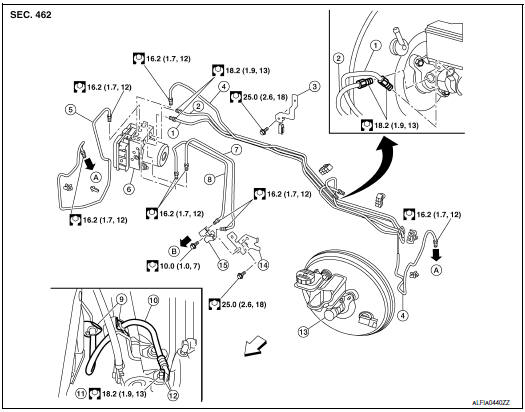

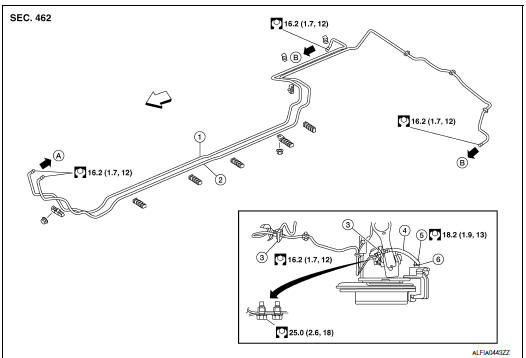

FRONT : Exploded View

- Master cylinder secondary to ABS actuator brake tube

- Master cylinder primary to ABS actuator brake tube

- Brake tube bracket

- Brake tube (LH)

- Brake tube (RH)

- ABS actuator and electric unit (control unit)

- ABS actuator to connector brake tube (LH)

- ABS actuator to connector brake tube (RH)

- Lock plate

- Front brake hose

- Union bolt

- Copper sealing washers

- Master cylinder

- Connector bracket

- Connector

- To front brake hose

- To rear brake tube

Front

Front

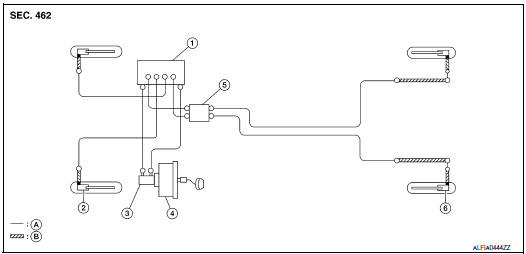

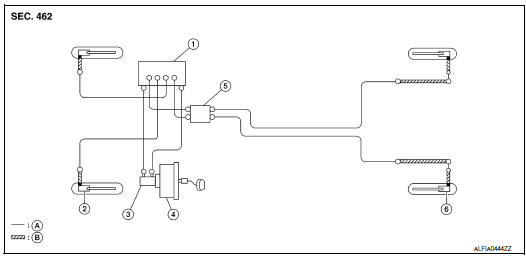

FRONT : Hydraulic Piping

- ABS actuator and electric unit (control unit)

- Front disc brake

- Master cylinder assembly

- Brake booster

- Connector

- Rear disc brake

- Brake tube

- Brake hose

: Flare nut

: Flare nut

: Union bolt

: Union bolt

FRONT : Removal and Installation

CAUTION:

- • Do not spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off immediately and wash with water if it gets on a painted surface.

- Do not allow foreign matter (e.g. dust) and oils other than brake fluid to enter the reservoir tank.

NOTE: When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

REMOVAL

- Remove wheels and tires using power tool.

- Loosen the flare nut with a flare nut wrench and separate the brake tube from the hose.

CAUTION:

- Do not scratch the flare nut and the brake pipe.

- All brake hoses and pipes must be free from excessive bending, twisting and pulling.

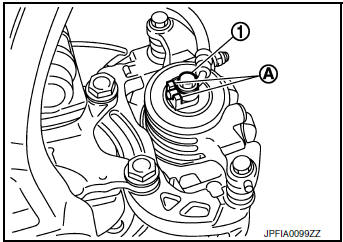

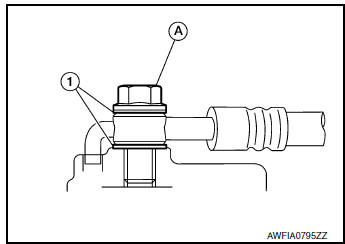

- Remove the union bolt (1) and the brake hose from the brake

caliper. Remove and discard the copper sealing washers.

CAUTION: Do not reuse copper sealing washers.

- Remove the lock plate and remove the brake hose.

INSTALLATION

CAUTION:Do not allow foreign matter (e.g. dust) and oils other than brake fluid to enter the reservoir tank.

- Assemble the union bolt (1) and the copper washers to the

brake hose and install it as an assembly to the brake caliper.

Align the brake hose pin to the projection (A) by aligning it with the brake caliper hole, and tighten the union bolt (1) to the specified torque.

CAUTION: Do not reuse copper sealing washers.

- Install the brake pipe to the brake hose, temporarily tighten the

flare nut by hand until it does not rotate further, and attach the

brake hose to the bracket with the lock plate.

CAUTION: Check that the brake hoses and pipes are not bent or twisted.

- Tighten the flare nut to the specified torque with a flare nut

crowfoot and a torque wrench.

CAUTION: Do not scratch the flare nut and the brake pipe.

- Refill with new brake fluid and perform the air bleeding. Refer to

BR-16, "Bleeding Brake System".

CAUTION: Do not reuse drained brake fluid.

- Install the wheels and tires. Refer to WT-60, "Removal and Installation".

- Perform inspection after installation. Refer to BR-8, "Inspection".

REAR

REAR : Exploded View

- Rear brake pipe assembly (RH)

- Rear brake pipe assembly (LH)

- Lock plate

- Rear brake hose

- Union bolt

- Copper sealing washers

- To brake pipe connector

- To rear brake hose

Front

Front

REAR : Hydraulic Piping

- ABS actuator and electric unit (control unit)

- Front disc brake

- Master cylinder assembly

- Brake booster

- Connector

- Rear disc brake

- Brake tube

- Brake hose

: Flare nut

: Flare nut

: Union bolt

: Union bolt

REAR : Removal and Installation

CAUTION:

- Do not spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off immediately and wash with water if it gets on a painted surface.

- Do not allow foreign matter (e.g. dust) and oils other than brake fluid to enter the reservoir tank.

NOTE: When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

REMOVAL

- Remove wheels and tires using power tool.

- Loosen the flare nut with a flare nut wrench and separate the brake tube from the hose.

CAUTION:

- Do not scratch the flare nut and the brake pipe.

- All brake hoses and pipes must be free from excessive bending, twisting and pulling.

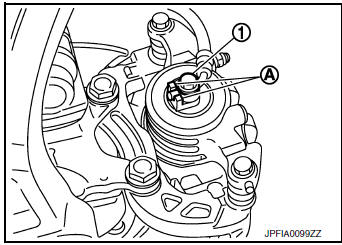

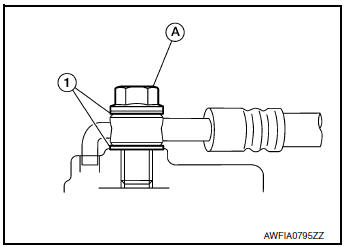

- Remove the union bolt (A) and the brake hose from the brake

caliper. Remove and discard the copper sealing washers (1).

CAUTION: Do not reuse copper sealing washers.

- Remove the lock plate and remove the brake hose.

INSTALLATION

CAUTION: Do not allow foreign matter (e.g. dust) and oils other than brake fluid to enter the reservoir tank.

- Assemble the union bolt (A) and the copper sealing washers (1)

to the brake hose and install it as an assembly to the brake caliper.

Align the brake hose L-pin by aligning it with the brake caliper hole, and tighten the union bolt (A) to the specified torque.

CAUTION: Do not reuse copper sealing washers.

- Install the brake pipe to the brake hose, temporarily tighten the

flare nut by hand until it does not rotate further, and attach the

brake hose to the bracket with the lock plate.

CAUTION: Check that the brake hoses and pipes are not bent or twisted.

- Tighten the flare nut to the specified torque with a flare nut

crowfoot and a torque wrench.

CAUTION: Do not scratch the flare nut and the brake pipe.

- Refill with new brake fluid and perform the air bleeding. Refer to

BR-16, "Bleeding Brake System".

CAUTION: Do not reuse drained brake fluid.

- Install the wheels and tires. Refer to WT-60, "Removal and Installation".

- Perform inspection after installation. Refer to BR-8, "Inspection".

Brake pedal

Brake pedal

Exploded View

Rivet

Clevis pin

Brake pedal

Brake pedal pad

Clip

Snap pin

Stop lamp switch

Brake pedal position switch

Removal and Installation

REMOVAL

...

Brake master cylinder

Brake master cylinder

Exploded View

Reservoir cap

Oil strainer

Reservoir tank

Brake fluid level sensor

Cylinder body

Pin

O-ring

Grommet

: Apply PBC (Poly Butyl

Cuprysil) grease or sil ...

Other materials:

P0507 ISC system

Description

The ECM controls the engine idle speed to a specified level through the fine

adjustment of the air, which is let

into the intake manifold, by operating the electric throttle control actuator.

The operating of the throttle valve is

varied to allow for optimum control of the engine ...

Instrument panel

Vent

Headlight/fog light (if so equipped)/turn signal switch

Meters, gauges, warning/indicator

lights and Vehicle Information Display

Windshield wiper/washer switch and rear window wiper/washer switch

/Ignition switch (if so equipped)

Push-button ...

Passenger side door mirror defogger

Description

Heats the heating wire with the power supply from the rear window defogger

relay to prevent the door mirror

from fogging up.

Component Function Check

1.CHECK DOOR MIRROR DEFOGGER RH

Check that the heating wire of door mirror defogger RH is heated when turning

the rear window def ...