Nissan Rogue Service Manual: Basic inspection

DIAGNOSIS AND REPAIR WORK FLOW

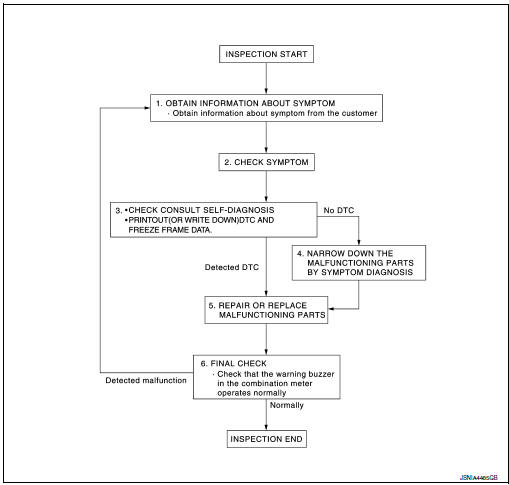

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the conditions and environment under which the malfunction occurred.

>> GO TO 2.

2.CHECK SYMPTOM

- Check the symptom based on the information obtained from the customer.

- Check if any other malfunctions are present.

> GO TO 3.

3.CHECK CONSULT SELF-DIAGNOSIS RESULTS

- Connect CONSULT and perform "self-diagnosis". Refer to WCS-27, "DTC Index".

- When DTC is detected, follow the instructions below:

- Record DTC and Freeze Frame Data.

Are self-diagnosis results normal? YES >> GO TO 4.

NO >> GO TO 5.

4.NARROW DOWN MALFUNCTIONING PARTS BY SYMPTOM DIAGNOSIS

Perform symptom diagnosis and narrow down the malfunctioning parts.

>> GO TO 5.

5.REPAIR OR REPLACE MALFUNCTIONING PARTS

Repair or replace malfunctioning parts.

NOTE: If DTC is displayed, erase DTC after repairing or replacing malfunctioning parts.

>> GO TO 6.

6.FINAL CHECK

Check that the warning buzzer in the combination meter operates normally.

Does it operate normally? YES >> Inspection End.

NO >> GO TO 1.

Wiring diagram

Wiring diagram

Wiring Diagram

...

Other materials:

Maintenance requirements

Your NISSAN is designed to have minimum maintenance

requirements with long service intervals

to save you both time and money. However, some

day-to-day and regular maintenance is essential

to maintain your NISSAN’s good mechanical

condition, as well as its emissions and engine

performance.

...

LDW system operation

LDW system operation

The LDW system operates above approximately

45 MPH (70 km/h).

When the vehicle approaches either the left or

the right of the traveling lane, the LDW system

will chime a sound and the LDW light on the

instrument panel will blink to alert the driver

The LDW system is ...

Fusible link inspection

How To Check

A melted fusible link can be detected either by visual inspection or by

feeling with finger tip. If its condition is

questionable, use circuit tester or test lamp.

Fusible link

With stop/start system

Without stop/start system*

*: Not applicable

CAUTION:

If ...