Nissan Rogue Service Manual: Basic inspection

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.INTERVIEW CUSTOMER

Interview the customer to obtain as much information as possible about the conditions and environment under which the malfunction occurred.

>> GO TO 2.

2.SYMPTOM CHECK

Verify symptoms.

>> GO TO 3.

3.CHECK FOR DTCS

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

- Check DTC.

Is any DTC detected? YES >> GO TO 4.

NO >> GO TO 5.

4.PERFORM DTC DIAGNOSTIC PROCEDURE

Perform the diagnostic procedure for the detected DTC. Refer to HAC-134, "DTC Inspection Priority Chart".

>> GO TO 7.

5.OPERATION CHECK

Perform the operation check. Refer to HAC-148, "Work Procedure".

>> GO TO 6.

6.SYMPTOM DIAGNOSIS

Check the symptom diagnosis table. Refer to HAC-174, "Symptom Table".

>> GO TO 8.

7.VERIFY REPAIR.

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

- Check DTC.

Is any DTC detected? YES >> GO TO 4.

NO >> GO TO 8.

8.PERFORM FINAL OPERATION CHECK

Perform the operation check. Refer to HAC-148, "Work Procedure".

Does it operate normally? YES >> Inspection End.

NO >> GO TO 2.

OPERATION INSPECTION

Work Procedure

DESCRIPTION

The purpose of the operational check is to check that the individual system operates normally.

Check condition : Engine running at normal operating temperature.

Check condition : Blower control dial in OFF position.

Check condition : REC off (LED extinguished).

Check condition : VENT selected (LED illuminated).

Check condition : DEF off (LED extinguished).

OPERATION INSPECTION

1.CHECK BLOWER

- Rotate the blower control dial clockwise one detent. Blower should operate on low speed.

- Rotate the blower control dial one detent at a time, and continue checking blower speed until all speeds are checked.

- Leave blower on maximum speed.

Is the test result normal? YES >> GO TO 2.

NO >> Refer to HAC-167, "Diagnosis Procedure".

2.CHECK A/C SWITCH LED

- Press A/C switch.

- A/C switch indicator should turn ON.

Is the test result normal? YES >> GO TO 3.

NO >> Refer to HAC-166, "FRONT A/C CONTROL : Diagnosis Procedure".

3.CHECK A/C SWITCH

Confirm that the compressor clutch engages (sound or visual inspection).

Is the test result normal? YES >> GO TO 4.

NO >> Refer to HAC-171, "Diagnosis Procedure".

4.CHECK FRONT AIR CONTROL MODE LEDS

- Press D/F (

), FOOT

(

), FOOT

( ), B/L

), B/L

, and VENT

, and VENT

, MAX A/C, and DEF (

, MAX A/C, and DEF ( ).

). - Each button indicator should illuminate.

Is the test result normal? YES >> GO TO 5.

NO >> Refer to HAC-166, "FRONT A/C CONTROL : Diagnosis Procedure".

5.CHECK DISCHARGE AIR

- Press D/F (

), FOOT

(

), FOOT

( ), B/L

), B/L

, and VENT

, and VENT and DEF (

and DEF (  ).

). - Confirm that discharge air comes out according to the air distribution table. Refer to HAC-120, "Door Control".

Is the test result normal? YES >> GO TO 6.

NO >> Refer to HAC-174, "Symptom Table".

6.CHECK REC LED

- Press DEF (

) and

make sure LED is off.

) and

make sure LED is off. - Make sure VENT (

)

or B/L (

)

or B/L (  ) is selected.

) is selected. - Press REC (

)

switch one time. REC indicator should illuminate.

)

switch one time. REC indicator should illuminate. - Press REC (

) switch one

more time. REC indicator should go off.

) switch one

more time. REC indicator should go off.

Is the test result normal? YES >> GO TO 7.

NO >> Refer to HAC-166, "FRONT A/C CONTROL : Diagnosis Procedure".

7.CHECK INTAKE DOOR OPERATION

- Press REC (

)

switch one time. REC indicator should illuminate.

)

switch one time. REC indicator should illuminate. - Listen to the sound of the air coming out of the vent.

- Press REC (

)

switch one more time. REC indicator should go off.

)

switch one more time. REC indicator should go off. - There should be an audible change to the sound of the air flowing out of the vent.

Is the test result normal? YES >> GO TO 8.

NO >> Refer to HAC-157, "Diagnosis Procedure".

8.CHECK TEMPERATURE DECREASE

- Press A/C switch.

- Rotate temperature control dial counterclockwise until maximum cold.

- Check for cold air at selected discharge air outlets.

Is the test result normal? YES >> GO TO 9.

NO >> Refer to HAC-175, "Component Function Check".

9.CHECK TEMPERATURE INCREASE

- Rotate temperature control dial clockwise until maximum hot.

- Check for hot air at appropriate discharge air outlets.

Is the test result normal? YES >> Inspection End.

NO >> Refer to HAC-177, "Component Function Check".

SYSTEM SETTING

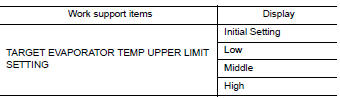

Target Evaporator Temp Upper Limit

DESCRIPTION

Set the target evaporator temperature upper limit.

HOW TO SET

With CONSULT

With CONSULT

Perform the “TARGET EVAPORATOR TEMP UPPER LIMIT SETTING” of HVAC work support item.

DOOR MOTOR STARTING POSITION RESET

Description

- Reset signal is transmitted from A/C auto amp. to air mix door motor,

intake door motor and mode door

motor. Starting position reset can be performed.

NOTE: During reset, DEF switch indicator blinks.

- When air mix door motor, intake door motor or mode door motor is removed and installed, always perform door motor starting position reset.

Work Procedure

1.PERFORM DOOR MOTOR STARTING POSITION RESET

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Select “Door Motor Starting Position Reset” in “ACTIVE TEST” mode of “HVAC” using CONSULT.

- Touch “Start” and wait a few seconds.

- Make sure the “COMPLETED” is displayed on CONSULT screen.

>> Inspection End.

Wiring diagram

Wiring diagram

MANUAL AIR CONDITIONING SYSTEM

Wiring Diagram

...

DTC/circuit diagnosis

DTC/circuit diagnosis

U1000 CAN COMM CIRCUIT

Description

CAN (Controller Area Network) is a serial communication system for real time

application. It is an on-vehicle

multiplex communication system with high data comm ...

Other materials:

VDC off indicator lamp

Component Function Check

1.CHECK VDC OFF INDICATOR LAMP FUNCTION (1)

Check that VDC OFF indicator lamp in combination meter turns ON for 1 second

after ignition switch is turned

ON.

CAUTION:

Never start the engine.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Proc ...

Preparation

Special Service Tools

The actual shape of the tools may differ from those illustrated here.

Tool number

(TechMate No.)

Tool name

Description

—

(J-46534)

Trim Tool Set

Removing trim components

...

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

...