Nissan Rogue Service Manual: Unit removal and installationEMBER

REAR SUSPENSION M

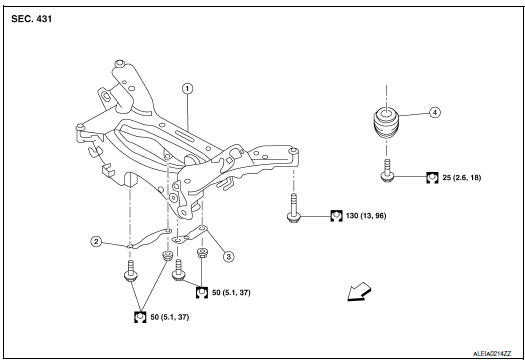

Exploded View

- Rear suspension member

- Suspension member stay (RH)

- Suspension member stay (LH)

- Bound bumper

Front

Front

Removal and Installation - FWD

REMOVAL

- Remove wheel and tires using power tool. Refer to WT-60, "Exploded View".

- Remove muffler assembly. Refer to EX-5, "Exploded View".

- Remove coil spring. Refer to RSU-8, "Removal and Installation - FWD".

- Remove lower link. Refer to RSU-17, "Removal and Installation".

- Remove upper link. Refer to BR-43, "BRAKE CALIPER ASSEMBLY : Removal and Installation".

- Remove rear stabilizer bar.Refer to RSU-21, "Removal and Installation".

- Remove rear shock absorber. Refer to RSU-14, "Removal and Installation".

- Set suitable jack under rear suspension member.

- Remove bolts from rear suspension member.

- Slowly lower suitable jack and remove rear suspension member.

CAUTION: Secure suspension assembly to a suitable jack while removing it.

INSTALLATION Installation is in the reverse order of the removal.

- When installing suspension member stay, face each arrow on the part toward the inside of the vehicle.

- Align the matching marks made during removal when reusing the disc brake rotor.

- Perform the final tightening of each parts removed when removing rear suspension assembly under unladen conditions.

- Check wheel sensor harness for proper connection. Refer to BRC-133, "REAR WHEEL SENSOR : Exploded View".

Removal and Installation - AWD

REMOVAL

- Remove wheel and tires using power tool. Refer to WT-60, "Exploded View".

- Remove muffler assembly. Refer to EX-5, "Exploded View".

- Remove coil spring. Refer to RSU-10, "Removal and Installation - AWD".

- Remove lower link. Refer to RSU-17, "Removal and Installation".

- Remove upper link. Refer to BR-43, "BRAKE CALIPER ASSEMBLY : Removal and Installation".

- Remove rear stabilizer bar.Refer to RSU-21, "Removal and Installation".

- Remove rear drive shaft. Refer to RAX-19, "Removal and Installation".

- Remove rear propeller shaft. Refer to DLN-99, "Removal and Installation".

- Remove rear final drive. Refer to DLN-119, "Removal and Installation".

- Remove rear shock absorber. Refer to RSU-14, "Removal and Installation".

- Set suitable jack under rear suspension member.

- Remove bolts from rear suspension member.

- Slowly lower suitable jack and remove rear suspension member.

CAUTION: Secure suspension assembly to a suitable jack while removing it.

- Perform the inspection after removal. Refer to RSU-23, "Inspection".

INSTALLATION

Installation is in the reverse order of the removal.

- When installing suspension member stay, face each arrow on the part toward the inside of the vehicle.

- Align the matching marks made during removal when reusing the disc brake rotor.

- Perform the final tightening of each parts removed when removing rear suspension assembly under unladen conditions.

- Check wheel sensor harness for proper connection. Refer to BRC-133, "REAR WHEEL SENSOR : Exploded View".

- Perform the inspection after installation. Refer to RSU-20,

"Inspection".

Inspection

INSPECTION AFTER REMOVAL

Check rear suspension member for deformation, cracks, or any other damage. Replace it if necessary.

INSPECTION AFTER INSTALLATION

- Adjust parking brake operation. Refer to PB-4, "Inspection and Adjustment".

- Check wheel alignment. Refer to RSU-6, "Inspection".

Rear stabilizer

Rear stabilizer

Exploded View

Rear stabilizer bar

Connecting rod (RH)

Rear stabilizer bar bushing

Rear stabilizer bar clamp

Connecting rod (LH)

Front

Removal and ...

Service data and specifications (SDS)

Service data and specifications (SDS)

Wheel Alignment (Unladen*1)

*1: Fuel, engine coolant, and lubricants are full. Spare tire, jack, hand

tools, and mats are in designated positions.

*2: Since an adjustment mechanism is not incl ...

Other materials:

Operating tips

When the engine coolant temperature and

outside air temperature are low, the air flow

from the foot outlets may not operate for a

maximum of 150 seconds. However, this is

not a malfunction. After the coolant temperature

warms up, air flow from the foot outlets

will operate normally.

...

Vehicle information

Identification information

Model Variation

FWD Model

AWD Model

Prefix and Suffix Designations

Identification Number

Air conditioner specification label

Emission control information label

Vehicle identification number chassis

number (center of bulkhead) ...

Passenger compartment

CAUTIONNever use a fuse of a higher or lower

amperage rating than specified on the

fuse box cover. This could damage the

electrical system or cause a fire.

If any electrical equipment does not operate,

check for an open fuse.

NOTE:

The fuse box is located on the driver ...