Nissan Rogue Service Manual: Tire pressure sensor

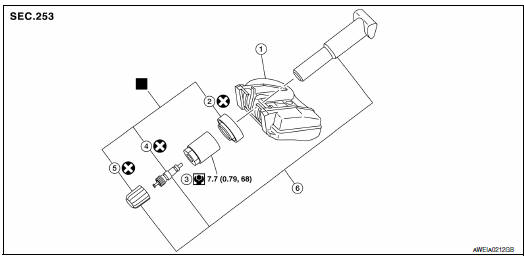

Exploded View

- Tire pressure sensor

- O-ring

- Valve stem nut

- Valve core

- Valve cap

- Valve stem assembly

: Parts that are replaced as a

set when the tire is replaced.

: Parts that are replaced as a

set when the tire is replaced.

Removal and Installation

REMOVAL

- Remove wheel and tire using power tool.

- Remove valve cap and valve core to deflate the tire.

NOTE: If the tire is to be reused, apply a matching mark on the tire in line with the position of the valve stem assembly for the purpose of wheel and tire balance adjustment after installation.

- Remove the valve stem nut and allow tire pressure sensor (1) to fall into tire.

- Lubricate the tire outside bead well with a suitable non-silicone lubricant, and remove outside of tire from the wheel. Reach inside the tire and remove the tire pressure sensor.

CAUTION:

- Do not use silicone lubricant. Use of silicone lubricant will deteriorate the tire and wheel.

- Be sure not to damage the wheel or tire pressure sensor.

- Do not allow lubricant to make contact with tire pressure sensor.

- Lubricate the tire inside bead well with a suitable non-silicone lubricant, and remove inside of tire from the wheel.

CAUTION:

- Do not use silicone lubricant. Use of silicone lubricant will deteriorate the tire and wheel.

- Be sure not to damage the wheel.

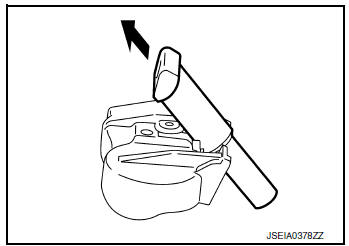

- Remove the valve stem from the tire pressure sensor as shown.

INSTALLATION

- Apply a suitable non-silicone lubricant to the tire inside bead.

CAUTION:

- Do not use silicone lubricant. Use of silicone lubricant will deteriorate the tire and wheel.

- Do not drop or strike the tire pressure sensor. Replace the tire pressure sensor if it has been dropped from higher than one meter.

- Install the tire inside bead (1) onto the wheel (2) in the position shown.

- Install the valve stem to the tire pressure sensor.

- Install the O-ring to the tire pressure sensor.

CAUTION:

- Do not reuse O-ring

- Insert O-ring to the base of the tire pressure sensor.

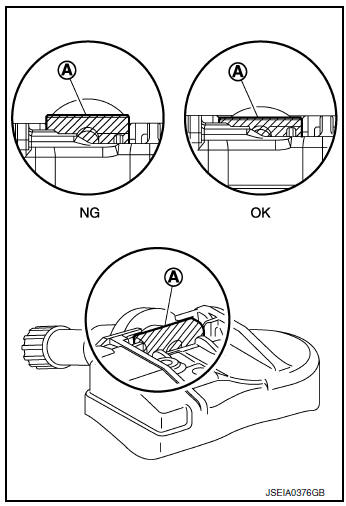

- The base of the valve stem (A) must be positioned in the groove of the metal plate as shown.

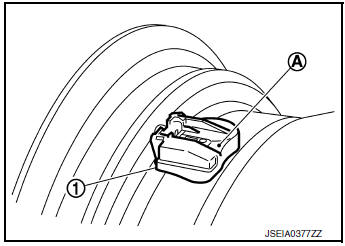

- Install tire pressure sensor (1) to wheel while pressing at position (A).

CAUTION:

- Check that O-ring contacts horizontally with wheel.

- Check that the base of the valve stem is positioned in the groove of the metal plate.

- Be sure that no burrs exist in the valve stem hole of the wheel.

- Install and tighten the valve stem nut to the specified torque.

Valve stem nut tightening torque : WT-61, "Exploded View"

CAUTION: Do not use power tool for installation.

- Place wheel on turntable of tire machine. Ensure that tire

pressure

sensor (1) is 270 degrees from mounting/dismounting head

(2).

NOTE: Do not touch tire pressure sensor with mounting head.

- Apply a suitable non-silicone lubricant to the tire outside bead.

CAUTION:

- Do not use silicone lubricant. Use of silicone lubricant will deteriorate the tire and wheel.

- Do not allow lubricant to make contact with tire pressure sensor.

- Install the tire outside bead onto the wheel as normal.

NOTE: If the tire is being reused, align the matching mark applied on the tire with the position of the valve stem assembly for the purpose of wheel and tire balance adjustment after installation. Make sure that the tire does not rotate relative to wheel.

- Install the valve core and inflate tire.

CAUTION: Do not reuse valve core.

- Install the valve cap.

CAUTION: Do not reuse valve cap.

- Balance the wheel and tire. Refer to WT-57, "Adjustment".

- Install wheel and tire in appropriate wheel position on vehicle.

Refer to WT-60, "Removal and Installation".

NOTE: If replacing the tire pressure sensor, then tire pressure sensor wake up operation must be performed.

Refer to WT-21, "Work Procedure".

- Adjust neutral position of steering angle sensor. Refer to BRC-70, "Work Procedure".

- . Perform the ID registration procedure. Refer to WT-21, "Work Procedure".

Remote keyless entry receiver

Removal and Installation

The Remote Keyless Entry Reciever is an integral part of the BCM (BODY CONTROL MODULE). Refer to BCS-75, "Removal and Installation" (WITH INTELLIGENT KEY SYSTEM) or BCS-135, "Removal and Installation"( WITHOUT INTELLIGENT KEY SYSTEM).

Wheel and tire

Wheel and tire

Exploded View

Wheel and tire

Wheel nut

Removal and Installation

REMOVAL

Remove wheel nuts using power tool.

Remove wheel and tire.

INSTALLATION

Installation ...

Service data and specifications (sds)

Service data and specifications (sds)

Wheel

ALUMINUM WHEEL

STEEL WHEEL

Tire Air Pressure

...

Other materials:

Heater and Air Conditioner (manual)

(if so equipped)

Heater and Air Conditioner

Fan speed control / system OFF dial / air

conditioning (A/C) button

Air flow control

buttons

Temperature control dial / MAX A/C button

Air recirculation button

Rear window and

outside mirror (if so

equipped) defroster but ...

CAN system (type 3)

MAIN LINE BETWEEN IPDM-E AND DLC CIRCUIT

Diagnosis Procedure

1.CHECK CONNECTOR

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Check the following terminals and connectors for damage, bend and

loose connection (connector side

and harn ...

Basic inspection

CONFIGURATION (CAN GATEWAY)

Work Procedure

1.WRITING MODE SELECTION

CONSULT Configuration

Select тАЬRe/programming, ConfigurationтАЭ of CAN gateway.

When writing saved data>>GO TO 2.

When writing manually>>GO TO 3.

2.PERFORM тАЬAFTER REPLACE ECUтАЭ OF тАЬREAD / WRITE CONFIGURA ...