Nissan Rogue Service Manual: Rear disc brake

BRAKE PAD

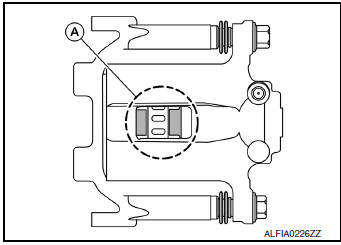

BRAKE PAD : Inspection

INSPECTION

Check brake pad wear thickness from an inspection hole (A) on cylinder body. Check using a scale if necessary.

Wear thickness : Refer to BR-55, "Rear Disc Brake".

DISC BRAKE ROTOR

DISC BRAKE ROTOR : Inspection

Appearance

Check surface of disc brake rotor for uneven wear, cracks or damage. Replace if any abnormal conditions exist.

Runout

- Check the wheel bearing axial end play before the inspection. Refer to RAX-6, "Inspection"(FWD) or RAX- 14, "Inspection"(AWD).

- Secure the disc brake rotor to the wheel hub and bearing with wheel nuts at two wheel nut locations.

- Measure the runout with a dial gauge 10 mm (0.39 in) from the disc brake rotor edge.

Runout : Refer to BR-55, "Rear Disc Brake".

- Find the installation position with a minimum runout by shifting the disc brake rotor-to-wheel hub and bearing installation position by one hole at a time if the runout exceeds the limit value.

- Refinish the disc brake rotor if the runout is outside the limit even after performing the above operation. When refinishing, use Tool.

Tool number : 38-PFM92

CAUTION:

- Check in advance that the thickness of the disc brake rotor is wear thickness + 0.3 mm (0.012 in) or more.

- If the thickness is less than wear thickness + 0.3 mm (0.012 in), replace the disc brake rotor.

Wear thickness : Refer to BR-55, "Rear Disc Brake".

Thickness

Check the thickness of the disc brake rotor using a micrometer.

Replace the disc brake rotor if the thickness is below the minimum thickness.

Minimum thickness : Refer to BR-55, "Rear Disc

Brake".

Thickness variation : Refer to BR-55, "Rear Disc

Brake".

Front disc brake

Front disc brake

BRAKE PAD

BRAKE PAD : Inspection

Check brake pad wear thickness from an inspection hole (A) on cylinder

body. Check using a scale if necessary.

Wear thickness : Refer to BR-55, "Front Dis ...

Other materials:

Removal and installation

POWER SOCKET

Removal and Installation

FRONT POWER SOCKET

Removal

Remove cluster lid C. Refer to IP-21, "Removal and Installation".

Release the pawls on the power socket and remove from the cluster

lid C.

Installation

Installation is in the reverse order of remov ...

Periodic maintenance

FUEL SYSTEM

Inspection

Inspect fuel lines, fuel filler cap, and fuel tank for improper attachment,

leaks, cracks, damage, loose connections, chafing or deterioration.

(A) : Engine

(B) : Fuel line

(C) : Fuel tank

If necessary, repair or replace damaged parts.

Quick Connector

CAUTION:

...

Diagnosis system (BCM) (without intelligent key system)

COMMON ITEM

COMMON ITEM : CONSULT Function (BCM - COMMON ITEM)

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with BCM.

Direct Diagnostic M

Description

Ecu Identification

The BCM part number is displayed.

Self Diagnostic Res ...