Nissan Rogue Service Manual: Power supply and ground circuit

BCM (BODY CONTROL SYSTEM) (WITH INTELLIGENT KEY SYSTEM)

BCM (BODY CONTROL SYSTEM) (WITH INTELLIGENT KEY SYSTEM) : Diagnosis Procedure

Regarding Wiring Diagram information, refer to BCS-50, "Wiring Diagram".

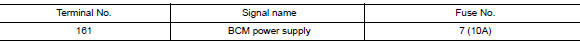

1. CHECK FUSE

Check that the following fuse is not blown.

Is the fuse blown? YES >> Replace the blown fuse after repairing the affected circuit.

NO >> GO TO 2.

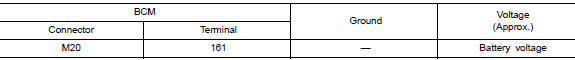

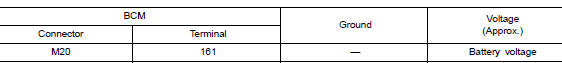

2. CHECK POWER SUPPLY CIRCUIT

- Disconnect BCM connector M20.

- Check voltage between BCM connector M20 and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness or connectors.

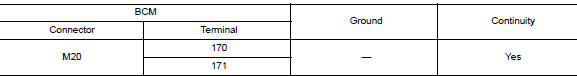

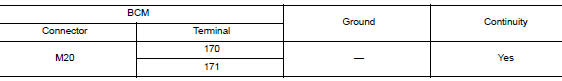

3. CHECK GROUND CIRCUIT

Check continuity between BCM connector M20 and ground.

Is the inspection result normal? YES >> Inspection End.

NO >> Repair or replace harness or connectors.

BCM (BODY CONTROL SYSTEM) (WITHOUT INTELLIGENT KEY SYSTEM)

BCM (BODY CONTROL SYSTEM) (WITHOUT INTELLIGENT KEY SYSTEM) : Diagnosis Procedure

Regarding Wiring Diagram information, refer to BCS-110, "Wiring Diagram".

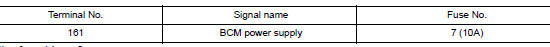

1. CHECK FUSE

Check that the following fuse is not blown.

Is the fuse blown? YES >> Replace the blown fuse after repairing the affected circuit.

NO >> GO TO 2.

2. CHECK POWER SUPPLY CIRCUIT

- Disconnect BCM connector M20.

- Check voltage between BCM connector M20 and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness or connectors.

3. CHECK GROUND CIRCUIT

Check continuity between BCM connector M20 and ground.

Is the inspection result normal? YES >> Inspection End.

NO >> Repair or replace harness or connectors.

POWER WINDOW MAIN SWITCH

POWER WINDOW MAIN SWITCH : Diagnosis Procedure

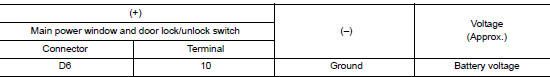

1.CHECK POWER SUPPLY CIRCUIT 1

- Turn ignition OFF.

- Disconnect main power window and door lock/unlock switch connector.

- Turn ignition switch ON.

- Check voltage between main power window and door lock/unlock switch harness connector and ground.

Is the inspection result normal? YES >> GO TO 2.

NO >> GO TO 4.

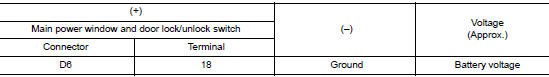

2.CHECK POWER SUPPLY CIRCUIT 2

1. Check voltage between main power window and door lock/unlock switch harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair power supply circuit.

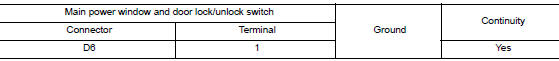

3.CHECK GROUND CIRCUIT

- Turn ignition switch OFF.

- Check continuity between main power window and door lock/unlock switch harness connector and ground.

Is the inspection result normal? YES >> Inspection End.

NO >> Repair or replace harness.

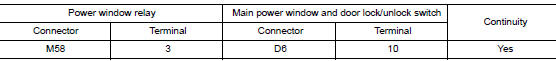

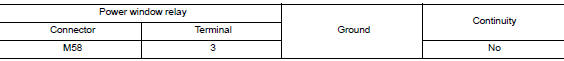

4.CHECK HARNESS CONTINUITY 1

- Turn ignition switch OFF.

- Disconnect power window relay connector.

- Check continuity between power window relay harness connector and main power window and door lock/ unlock switch harness connector.

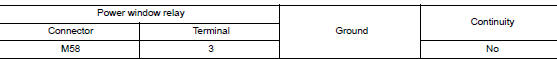

- Check continuity between power window relay harness connector and ground.

Is the inspection result normal? YES >> Refer to PWC-48, "Diagnosis Procedure".

NO >> Repair or replace harness.

FRONT POWER WINDOW SWITCH (PASSENGER SIDE)

FRONT POWER WINDOW SWITCH (PASSENGER SIDE) : Diagnosis Procedure

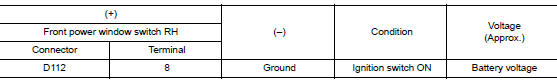

1.CHECK POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect front power window switch RH connector.

- Turn ignition switch ON.

- Check voltage between front power window switch RH harness connector and ground.

Is the inspection result normal? YES >> Inspection End.

NO >> GO TO 2.

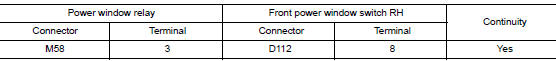

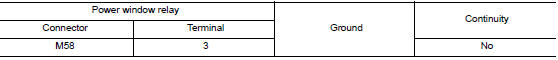

2.CHECK HARNESS CONTINUITY

- Turn ignition switch OFF.

- Disconnect power window relay connector.

- Check continuity between power window relay harness connector and front power window switch RH harness connector.

- Check continuity between the power window relay harness connector and ground.

Is the inspection result normal? YES >> Refer to PWC-48, "Diagnosis Procedure".

NO >> Repair or replace harness.

REAR POWER WINDOW SWITCH

REAR POWER WINDOW SWITCH : Diagnosis Procedure

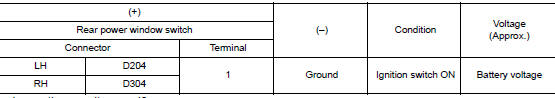

1.CHECK POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect rear power window switch connector.

- Turn ignition switch ON.

- Check voltage between rear power window switch harness connector and ground.

Is the inspection result normal? YES >> Inspection End.

NO >> GO TO 2.

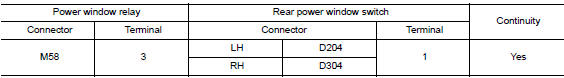

2.CHECK HARNESS CONTINUITY

- Turn ignition switch OFF.

- Disconnect power window relay connector.

- Check continuity between power window relay harness connector and rear power window switch harness connector.

- Check continuity between power window relay harness connector and ground.

Is the inspection result normal? YES >> Refer to PWC-48, "Diagnosis Procedure".

NO >> Repair or replace harness.

Front power window switch (passenger side)

Front power window switch (passenger side)

Description

Front power window motor RH will be operated if front power window switch RH

is operated.

Component Function Check

1. CHECK FRONT POWER WINDOW SWITCH RH FUNCTION

Check front power wi ...

Other materials:

Available views

WARNING

The distance guide line and the vehicle

width line should be used as a reference

only when the vehicle is on a paved,

level surface. The distance viewed on

the monitor may be different than the

actual distance between the vehicle and

displayed objects ...

Preparation

Special Service Tool

The actual shape of the tools may differ from those illustrated here

Tool number

(TechMate No.)

Tool name

Description

KV101207S0

( — )

Unified fuel lock ring wrench

Removing and installing fuel tank lock ring

—

(J-45747)

...

Basic inspection

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

Work flow

STEP

DESCRIPTION

STEP 1

Get detailed information about the conditions and the

environment when the incident occurred.

The following are key pieces of information required to make a good

analysis:

WH ...