Nissan Rogue Service Manual: Power supply and ground circuit

Diagnosis Procedure

Regarding Wiring Diagram information, refer to PCS-24, "Wiring Diagram".

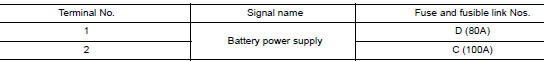

1. CHECK FUSE AND FUSIBLE LINKS

Check that the following IPDM E/R fuse or fusible links are not blown.

Is the fuse blown? YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2.

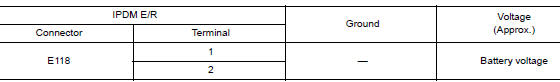

2. CHECK BATTERY POWER SUPPLY CIRCUIT

- Disconnect IPDM E/R connector E118.

- Check voltage between IPDM E/R connector E118 and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness or connectors.

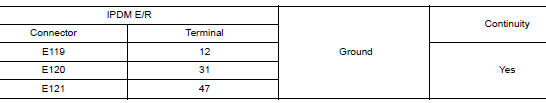

3. CHECK GROUND CIRCUIT

- Disconnect IPDM E/R connectors E119, E120 and E121.

- Check continuity between IPDM E/R connectors and ground.

Is the inspection result normal? YES >> Inspection End.

NO >> Repair or replace harness or connectors.

U1000 CAN COMM CIRCUIT

U1000 CAN COMM CIRCUIT

Description

CAN communication allows a high rate of information transmission through the

two communication lines

(CAN-H line and CAN-L line) connecting various control units in the system. Each

...

Parking brake switch

Parking brake switch

Component Function Check

1.CHECK PARKING BRAKE SWITCH OPERATION

Check that brake warning lamp in combination meter turns ON/OFF when parking

brake is operated.

Is the inspection result normal?

...

Other materials:

Front wiper motor

Removal and Installation

REMOVAL

Remove the front drive assembly. Refer to WW-66, "Removal and

Installation".

Remove the bolts (A) from the front wiper drive assembly (1)

and the front wiper motor (2).

Separate the wiper motor (1) from the front wiper drive ...

Front seat

DRIVER SIDE

DRIVER SIDE : Exploded View

POWER SEAT

Headrest

Seatback support

Seatback board

Seatback heater (if equipped)

Seatback trim

Seatback pad

Seat cushion outer finisher (RH)

Seat cushion rear finisher

(RH)

Seat cushion inner fini ...

C1735 ignition signal

DTC Logic

NOTE:

The Signal Tech II Tool [- (J-50190)] can be used to perform the following

functions. Refer to the Signal Tech II

User Guide for additional information.

Activate and display TPMS sensor IDs

Display tire pressure reported by the TPMS sensor

Read TPMS DTC ...