Nissan Rogue Service Manual: Overdrive control switch

Component Function Check

1.CHECK O/D OFF INDICATOR LAMP FUNCTION

Check O/D OFF indicator lamp turns ON for approx. 2 seconds when ignition switch turns ON.

Is the inspection results normal? YES >> GO TO 2.

NO >> Go to TM-181, "Diagnosis Procedure".

2.CHECK OVERDRIVE CONTROL SWITCH FUNCTION

- Shift the selector lever to “D” position.

- Check that O/D OFF indicator lamp turns ON/OFF when overdrive control switch is operated.

Is the inspection results normal? YES >> INSPECTION END

NO >> Go to TM-178, "Diagnosis Procedure".

Diagnosis Procedure

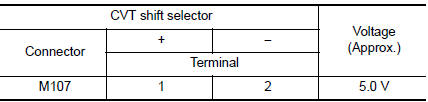

1.CHECK OVERDRIVE CONTROL SWITCH CIRCUIT

- Turn ignition switch OFF.

- Disconnect CVT shift selector connector.

- Turn ignition switch ON.

- Check voltage between CVT shift selector harness connector terminals.

Is the inspection result normal? YES >> GO TO 2.

NO >> GO TO 4.

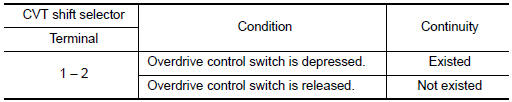

2.CHECK CVT SHIFT SELECTOR CIRCUIT

Check continuity between CVT shift selector harness connector terminals.

Is the inspection result normal? YES >> GO TO 7.

NO >> GO TO 3.

3.CHECK OVERDRIVE CONTROL SWITCH

Check overdrive control switch. Refer to TM-179, "Component Inspection".

Is the inspection result normal? YES >> Repair CVT shift selector assembly. Refer to TM-194, "Removal and Installation".

NO >> Replace selector lever knob. Refer to TM-194, "Removal and Installation".

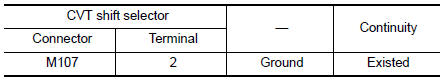

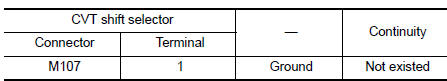

4.CHECK GROUND CIRCUIT

Check continuity between CVT shift selector harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace malfunctioning parts.

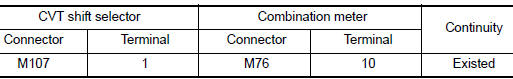

5.CHECK CIRCUIT BETWEEN CVT SHIFT SELECTOR AND COMBINATION METER (PART 1)

- Turn ignition switch OFF.

- Disconnect combination meter connector.

- Check continuity between CVT shift selector harness connector terminal and combination meter harness connector terminal.

the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace malfunctioning parts.

6.CHECK CIRCUIT BETWEEN CVT SHIFT SELECTOR AND COMBINATION METER (PART 2)

Check continuity between CVT shift selector harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 7.

NO >> Repair or replace malfunctioning parts.

7.CHECK COMBINATION METER INPUT/OUTPUT SIGNAL

- Connect all of disconnected connectors.

- Turn ignition switch ON.

- Select “Data Monitor” in “METER/M&A”.

- Select “O/D OFF SW”.

- Check that “O/D OFF SW” turns ON/OFF when overdrive control switch is operated. Refer to MWI-24, "Reference Value".

Is the inspection result normal?

YES >> Check intermittent incident. Refer to GI-41, "Intermittent Incident".

NO >> Replace combination meter. Refer to MWI-82, "Removal and Installation".

Component Inspection

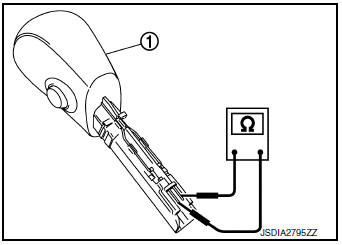

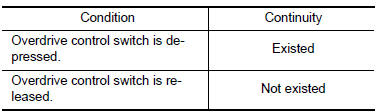

1.CHECK OVERDRIVE CONTROL SW

Check continuity between wires of shift selector knob 1.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace shift selector knob. Refer to TM-194, "Removal and Installation".

Main power supply and ground circuit

Main power supply and ground circuit

Diagnosis Procedure

1.CHECK TCM POWER CIRCUIT (PART 1)

Turn ignition switch OFF.

Disconnect TCM connector.

Check voltage between TCM harness connector terminals and ground.

...

O/D off indicator lamp

O/D off indicator lamp

Component Function Check

1.CHECK O/D OFF INDICATOR LAMP FUNCTION

Check O/D OFF indicator lamp turns ON for approx. 2 seconds when ignition

switch turns ON.

Is the inspection results normal?

YE ...

Other materials:

Lumbar support switch

Exploded View

Seat cushion outer finisher

Lumbar support switch

Clip

Pawl

Removal and Installation

REMOVAL

Using a suitable tool release clips and remove seat cushion

outer finisher (1).

: Clip

Disconnect harness connector from lumbar support switch.

...

Front wiper arm

Exploded View

Front wiper blade (RH)

Front wiper arm (RH)

Front wiper arm cover

Front wiper drive assembly

Front wiper arm (LH)

Front wiper blade (LH)

Removal and Installation

REMOVAL

Move front wiper into the service position by turning the ignit ...

Front wiper blade

Exploded View

Wiper blade (RH)

Wiper arm (RH)

Wiper arm cover

Front wiper drive assembly

Wiper arm (LH)

Wiper blade (LH)

Removal and Installation

REMOVAL

Move front wiper into the service position by turning the ignition

switch ON, then quickly push the wiper

...