Nissan Rogue Service Manual: Condenser

Exploded View

- Air guide (LH)

- Condenser upper bracket (LH)

- Condenser (includes liquid tank)

- Condenser upper bracket (RH)

- Air guide (RH)

- Refrigerant pressure sensor

- Condenser lower bracket (RH)

- Condenser lower bracket (LH)

CONDENSER

CONDENSER : Removal and Installation

REMOVAL

CAUTION: Before servicing, turn the ignition switch off, disconnect both battery cables and wait at least three minutes.

- Disconnect the negative and positive battle terminals and wait at least three minutes. Refer to PG-75, "Removal and Installation (Battery)".

- Discharge the refrigerant. Refer to HA-23, "Recycle Refrigerant".

- Remove front air duct. Refer to EM-24, "Removal and Installation".

- Remove front bumper fascia. Refer to EXT-17, "Removal and Installation".

- Remove front combination lamp (RH). Refer to EXL-119, "Removal and Installation".

- Remove air guides (LH/RH). Refer to HA-37, "Exploded View".

- Remove crash zone sensor. Refer to SR-22, "Removal and Installation".

- Disconnect the harness connector from the refrigerant pressure sensor.

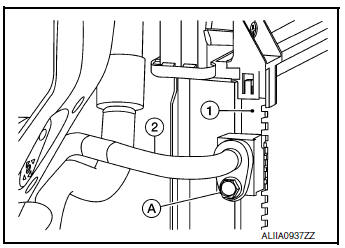

- Remove the bolt (A) that retains the high-pressure flexible hose (2) to the condenser (1).

CAUTION: Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

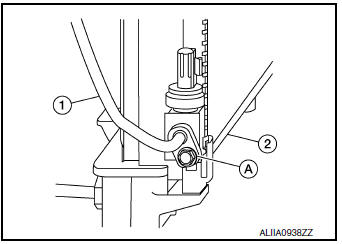

- Remove bolt (A) that retains high-pressure pipe (1) to condenser (2).

- Remove the condenser bracket bolts and condenser.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Tighten bolts to specification. Refer to HA-32, "Exploded View".

- Do not reuse O-rings.

- Apply A/C oil to new O-rings for installation.

- After charging the refrigerant, check for leaks. Refer to HA-21, "Leak Test".

LIQUID TANK

LIQUID TANK : Removal and Installation

The liquid tank is serviced as an assembly with the condenser. Refer to HA-37, "CONDENSER : Removal and Installation".

REFRIGERANT PRESSURE SENSOR

REFRIGERANT PRESSURE SENSOR : Removal and Installation

REMOVAL

- Discharge the refrigerant. Refer to HA-23, "Recycle Refrigerant".

- Remove front air duct. Refer to EM-24, "Removal and Installation".

- Remove front bumper fascia. Refer to EXT-17, "Removal and Installation".

- Remove air guide (RH). Refer to HA-37, "Exploded View".

- Disconnect the harness connector from the refrigerant pressure sensor and remove.

CAUTION: Cap or wrap the opening of the refrigerant pressure sensor with suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not reuse O-ring.

- Apply A/C oil to new O-rings for installation.

- After charging the refrigerant, check for leaks. Refer to HA-21, "Leak Test".

Cooler pipe and hose

Cooler pipe and hose

Exploded View

Condenser

High-pressure flexible hose

Low-pressure flexible hose

Low-pressure pipe

Heating and cooling unit assembly

High-pressure pipe

Compressor

...

Heating and cooling unit assembly

Heating and cooling unit assembly

Exploded View

Steering Member

Heating and cooling unit assembly

Steering member

Bolt

Nut

Automatic Air Conditioning

Wiring harness

Air mix door duct (LH)

...

Other materials:

Preparation

Special Service Tool

The actual shape of the tool may differ from those illustrated here.

Tool number

(TechMate No.)

Tool name

Description

KV991J0080

(J-45741)

ABS active wheel sensor tester

Checking operation of ABS active wheel sensors

Comm ...

Wiring diagram

MANUAL AIR CONDITIONING SYSTEM

Wiring Diagram

...

CVT oil warmer

Exploded View

Transaxle assembly

CVT oil warmer

: N·m (kg-m, in-lb)

Removal and Installation

REMOVAL

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur

from high pressure

engine coolant escaping from the radiator. Wrap a thick cloth around ...