Nissan Rogue Service Manual: Charging system preliminary inspection

Diagnosis Procedure

1.CHECK BATTERY TERMINALS CONNECTION

Check if battery terminals are clean and tight.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair battery terminal connection. Confirm repair by performing complete Charging system test using EXP-800 NI or GR8-1200 NI (if available). Refer to the applicable Instruction Manual for proper testing procedures.

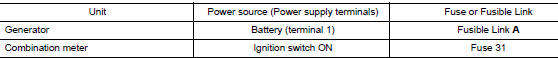

2.CHECK FUSE

Check for blown fuse and fusible link.

Is the inspection result normal? YES >> GO TO 3.

NO >> Replace the blown fuse or fusible link after repairing the affected circuit.

3.CHECK DRIVE BELT TENSION

Check drive belt tension. Refer to MA-13, "DRIVE BELTS : Tension Adjustment".

Is the inspection result normal? YES >> Inspection End.

NO >> Repair as needed.

Power generation voltage variable control system operation

inspection

Power generation voltage variable control system operation

inspection

Diagnosis Procedure

Regarding Wiring Diagram information. Refer to CHG-7, "Wiring Diagram".

CAUTION:

When performing this inspection, always use a charged battery that has completed

the ...

Other materials:

DTC/Circuit diagnosis

C1201 AWD CONTROL UNIT

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

C1201

CONTROLLER FAILURE

(Control unit failure)

Malfunction has occurred inside AWD control unit.

POSSIBLE CAUSE

Int ...

Towing load/specification

TOWING LOAD/SPECIFICATION CHART

U.S. and Canada

Maximum Towing Capacity*1

1,100lb.

(500 kg)

Maximum Tongue Load

110 lb.

(50 kg)

Maximum Gross Combined Weight Rating

5,291 lb.

(2,400 kg)

*1: The towing capacity ...

C1144 incomplete steering angle sensor adjustment

DTC Logic

DTC DETECTION LOGIC

DTC

Display Item

Malfunction detected condition

Possible causes

C1144

ST ANG SEN SIGNAL

When neutral position adjustment of steering angle

sensor is not complete.

Harness or connector

Steering angle sensor

&n ...