Nissan Rogue Service Manual: Basic inspection

DIAGNOSIS AND REPAIR WORK FLOW

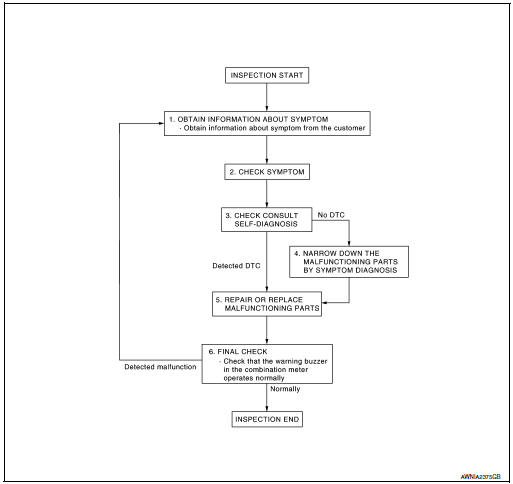

Work flow

OVERALL SEQUENCE

DETAILED FLOW

1.OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the conditions and environment under which the malfunction occurred.

>> GO TO 2.

2.CHECK SYMPTOM

- Check the symptom based on the information obtained from the customer.

- Check if any other malfunctions are present.

>> GO TO 3.

3.CHECK CONSULT SELF-DIAGNOSIS RESULTS

Connect CONSULT and perform "self-diagnosis". Refer to MWI-30, "DTC Index".

Are self-diagnosis results normal? YES >> GO TO 4.

NO >> GO TO 5.

4.NARROW DOWN MALFUNCTIONING PARTS BY SYMPTOM DIAGNOSIS

Perform symptom diagnosis and narrow down the malfunctioning parts.

>> GO TO 5.

5.REPAIR OR REPLACE MALFUNCTIONING PARTS

Repair or replace malfunctioning parts.

NOTE: If DTC is displayed, erase DTC after repairing or replacing malfunctioning parts.

>> GO TO 6.

6.FINAL CHECK

Check that the warning buzzer in the combination meter operates normally.

Does it operate normally? YES >> Inspection End.

NO >> GO TO 1.

Compass

Compass

Wiring Diagram

...

Other materials:

B0001, B0002 driver airbag module

DTC Logic

DTC DETECTION LOGIC

CONSULT name

DTC

DTC detecting condition

Repair order

DRIVER AIRBAG MODULE CIRCUIT

[OPEN]

B0001

Driver air bag module circuit

(DR1) is open

(including the spiral cable).

Refer to SRC-47, "Diagnosis Proced ...

Forward-facing child restraint installation

using the seat belts

WARNINGThe three-point seat belt with Automatic

Locking Retractor (ALR) must be used

when installing a child restraint. Failure to

use the ALR mode will result in the child

restraint not being properly secured. The

restraint could tip over or be loose and

cause injury to a c ...

Combination meter

Removal and Installation

REMOVAL

Disconnect the negative battery terminal. Refer to PG-77, "Removal

and Installation".

Remove the cluster lid A. Refer to IP-20, "Removal and

Installation".

Remove screws (A), from the combination meter (1).

...