Nissan Rogue Service Manual: Unit disassembly and assembly

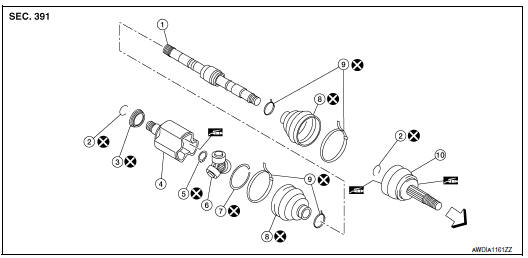

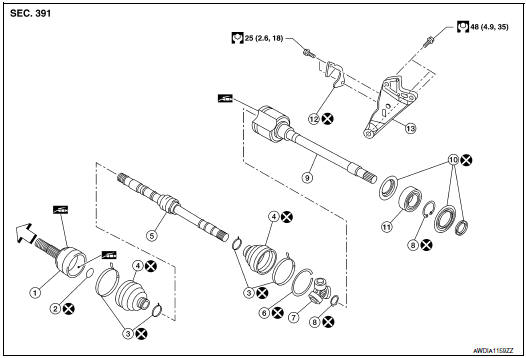

FRONT DRIVE SHAFT

Exploded View (LH)

- Shaft

- Circular clip

- Dust shield

- Housing

- Snap ring

- Spider assembly

- Stopper ring

- Boot

- Boot band

- Joint sub-assembly

Wheel side

Wheel side

Disassembly and Assembly (LH)

DISASSEMBLY

Transaxle Assembly Side

- Fix shaft with a vise.

CAUTION: Protect shaft using aluminum or copper plates when fixing with a vise.

- Remove boot bands, and then remove boot from housing.

- Remove stopper ring.

- Put matching marks on housing and shaft, and then pull out housing

from shaft.

CAUTION: Use paint or an equivalent for matching marks. Do not scratch the surfaces.

- Put matching marks (A) on the spider assembly and shaft.

CAUTION: Use paint or an equivalent for matching marks. Do not scratch the surfaces.

- Remove snap ring (1), and then remove spider assembly from shaft.

- Remove boot from shaft.

- Remove circular clip from housing (left side).

- Remove dust shield from housing.

- Clean old grease on housing with paper waste.

Wheel Side

- Fix shaft with a vise.

CAUTION: Protect shaft using aluminum or copper plates when fixing with a vise.

- Remove boot bands, and then remove boot from joint sub-assembly.

- Screw the drive shaft puller (A) 30 mm (1.18 in) or more into the thread of joint sub-assembly, and pull joint sub-assembly with a sliding hammer (B) from shaft.

CAUTION:

- If joint sub-assembly cannot be removed after five or more unsuccessful attempts, replace shaft and joint sub assembly as a set.

- Align sliding hammer and drive shaft and remove them by pulling forcibly

- Remove circular clip from shaft.

- Remove boot from shaft.

- Clean old grease on joint sub-assembly with paper waste while rotating ball cage.

ASSEMBLY

Transaxle Assembly Side

- Install new boot and boot bands to shaft.

CAUTION:

- Wrap serration on shaft with tape (A) to protect from damage

- Do not reuse boot and boot band.

- Remove the tape wrapped around the serration on shaft.

- To install the spider assembly (1), align it with the matching marks (A) on the shaft (2) put during the removal, and direct the serration mounting surface (B) to the shaft.

- Secure spider assembly onto shaft with snap ring (1).

CAUTION: Do not reuse snap ring.

- Apply the appropriate amount of grease to spider assembly and sliding surface.

- Assemble the housing onto spider assembly, and apply the specified amount of grease.

Grease amount : Refer to FAX-65, "Drive Shaft".

- Align matching marks put during the removal of housing.

- Install stopper ring.

CAUTION: Do not reuse stopper ring.

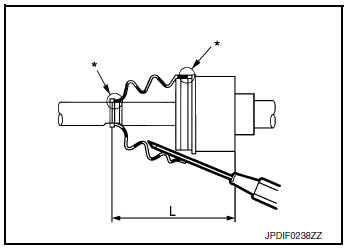

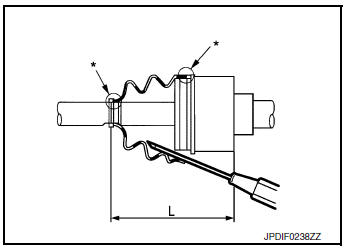

- Install boot securely into grooves (indicated by “*” marks)

shown.

CAUTION: If grease adheres to the boot mounting surface (indicated “*” mark) on shaft or housing, boot may be removed.

Remove all grease from the boot mounting surface.

- To prevent the deformation of the boot, adjust the boot installation length (L) to the value shown below by inserting the suitable tool into the inside of boot from the large diameter side of boot and discharging inside air.

Boots installed length (L) : Refer to FAX-65, "Drive Shaft".

CAUTION:

- If the boot installation length is outside the standard, it may cause breakage of boot.

- Be careful not to touch the inside of the boot with the tip of tool.

- Install new boot bands securely as shown.

CAUTION: Do not reuse boot band.

- Secure housing and shaft, and then make sure that they are in the correct position when rotating boot. Reinstall them with new boot bands when the mounting positions become incorrect.

- Install dust shield to housing (left side).

CAUTION: Do not reuse dust shield.

- Install circular clip to housing (left side).

CAUTION: Do not reuse circular clip.

Wheel Side

For further details, refer to the installation procedure of “FAX-44, "WHEEL SIDE : Removal and Installation"” for the drive shaft boot.

Exploded View (RH)

- Joint sub-assembly

- Circular clip

- Boot band

- Boot

- Shaft

- Damper band

- Dynamic damper

- Stopper ring

- Spider assembly

- Snap ring

- Housing

- Dust shield

- Support bearing

- Retainer

- Support bearing bracket

: Wheel side

: Wheel side

Disassembly and Assembly (RH)

DISASSEMBLY

Transaxle Assembly Side

- Fix shaft with a vise.

CAUTION: Protect shaft using aluminum or copper plates when fixing with a vise.

- Remove boot bands, and then remove boot from housing.

- Remove stopper ring.

- Put matching marks on housing and shaft, and then pull out housing from

shaft.

CAUTION: Use paint or an equivalent for matching marks. Do not scratch the surfaces.

- Put matching marks (A) on the spider assembly and shaft.

CAUTION: Use paint or an equivalent for matching marks. Do not scratch the surfaces.

- Remove snap ring (1), and then remove spider assembly from shaft.

- Remove boot from shaft.

- Remove circular clip from housing (left side).

- Remove dust shield from housing.

- Clean old grease on housing with paper waste.

Support Bearing

- Remove dust shield from housing.

- Remove snap ring (1).

- Press out support bearing from housing.

- Remove dust shield.

Wheel Side

- Fix shaft with a vise.

CAUTION: Protect shaft using aluminum or copper plates when fixing with a vise.

- Remove boot bands, and then remove boot from joint sub-assembly.

- Screw the drive shaft puller (A) 30 mm (1.18 in) or more into the thread of joint sub-assembly, and pull joint sub-assembly with a sliding hammer (B) from shaft.

CAUTION:

- If joint sub-assembly cannot be removed after five or more unsuccessful attempts, replace shaft and joint sub assembly as a set.

- Align sliding hammer and drive shaft and remove them by pulling forcibly.

- Remove circular clip from shaft.

- Remove boot from shaft.

- Clean old grease on joint sub-assembly with paper waste while rotating ball cage.

ASSEMBLY

Transaxle Assembly Side

- Wrap serration on shaft with tape (A) to protect boot from damage.

Install new boot and boot bands to shaft.

CAUTION: Do not reuse boot and boot band.

- Remove the tape wrapped around the serration on shaft.

- To install the spider assembly (1), align it with the matching marks (A) on the shaft (2) put during the removal, and direct the serration mounting surface (B) to the shaft.

- Secure spider assembly onto shaft with snap ring (1).

CAUTION: Do not reuse snap ring.

- Apply the appropriate amount of grease to spider assembly and sliding surface.

- Assemble the housing onto spider assembly, and apply the specified amount of grease.

Grease amount : Refer to FAX-65, "Drive Shaft".

- Align matching marks put during the removal of housing.

- Install stopper ring.

CAUTION: Do not reuse stopper ring.

- Install boot securely into grooves (indicated by “*” marks) shown

in the figure.

CAUTION: If grease adheres to the boot mounting surface (indicated “*” mark) on shaft or housing, boot may be removed.

Remove all grease from the boot mounting surface.

- To prevent the deformation of the boot, adjust the boot installation length (L) to the value shown below by inserting the suitable tool into the inside of boot from the large diameter side of boot and discharging inside air.

Boots installed length (L) : Refer to FAX-65, "Drive Shaft".

CAUTION:

- If the boot installation length is outside the standard, it may cause breakage of boot.

- Be careful not to touch the inside of the boot with the tip of tool.

- Install new boot bands securely as shown in the figure.

CAUTION: Do not reuse boot band.

- Secure housing and shaft, and then make sure that they are in the correct position when rotating boot. Reinstall them with new boot bands when the mounting positions become incorrect.

- Install dust shield to housing (left side).

CAUTION: Do not reuse dust shield.

- Install circular clip to housing (left side).

CAUTION: Do not reuse circular clip.

Support Bearing

- Install dust shield on housing.

CAUTION: Do not reuse dust shield.

- Press support bearing (1) onto housing to using the suitable tool (A).

- Install snap ring.

CAUTION: Do not reuse snap ring.

- Install dust shields.

CAUTION: Do not reuse dust shields.

Wheel Side

For further details, refer to the installation procedure of “FAX-44, "WHEEL SIDE : Removal and Installation"” for the drive shaft boot.

Removal and installation

Removal and installation

FRONT WHEEL HUB

Exploded View

Wheel hub and bearing

Cotter pin

Nut retainer

Wheel hub lock nut

Hub bolt

Splash guard

Steering knuckle

Removal and In ...

Service data and specifications (SDS)

Service data and specifications (SDS)

Wheel Bearing

Drive Shaft

Drive Shaft Specifications

*Always check with the Parts Department for the latest parts information.

Dynamic Damper Specifications

Boot Band Specification

...

Other materials:

Back door window glass

Exploded View

Back door window glass

Clip

Clip

Removal and Installation

REMOVAL

Remove back door finisher. Refer to INT-38, "Removal and

Installation".

Remove back door lock. Refer to DLK-263, "DOOR LOCK : Removal and

Installation" (for i ...

Engine oil

Inspection

ENGINE OIL LEVEL

NOTE:

Before starting engine, put vehicle horizontally and check the engine oil level.

If engine is already started, stop

it and allow 5 minutes before checking.

Pull out oil level gauge and wipe it clean.

Insert oil level gauge and check the engin ...

P0507 ISC system

Description

The ECM controls the engine idle speed to a specified level through the fine

adjustment of the air, which is let

into the intake manifold, by operating the electric throttle control actuator.

The operating of the throttle valve is

varied to allow for optimum control of the engine ...