Nissan Rogue Service Manual: Removal and installation

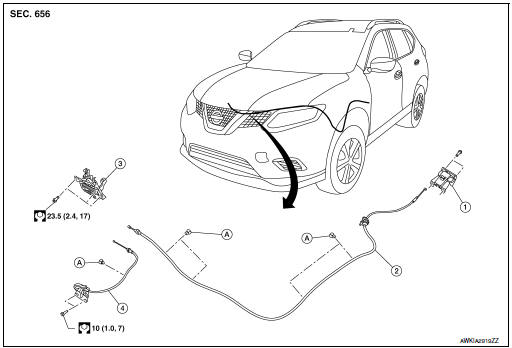

HOOD

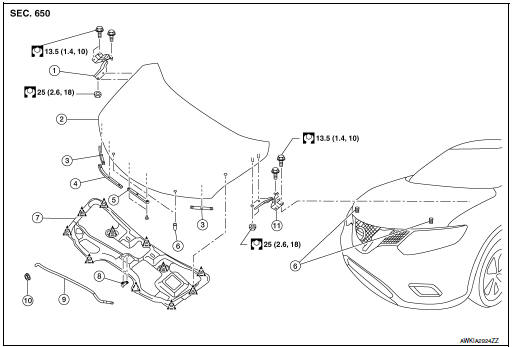

Exploded View

- Hood hinge (RH)

- Hood

- Hood side seal

- Hood front seal

- Hood center seal

- Bumper rubber

- Hood insulator

- Hood rod clamp

- Hood support rod

- Hood rod grommet

- Hood hinge (LH)

HOOD ASSEMBLY

HOOD ASSEMBLY : Removal and Installation

CAUTION:

- Use two people when removing or installing hood assembly due to its heavy weight.

- Use protective tape or shop cloths to protect surrounding components from damage during removal and installation of hood assembly.

REMOVAL

- Support the hood assembly using a suitable tool.

WARNING: Bodily injury may occur if hood assembly is not supported properly when removing hood assembly.

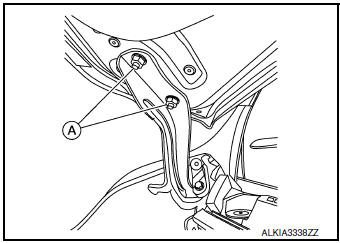

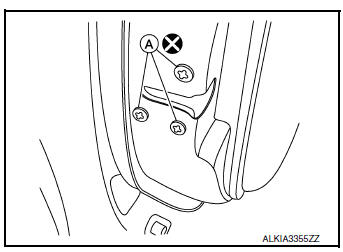

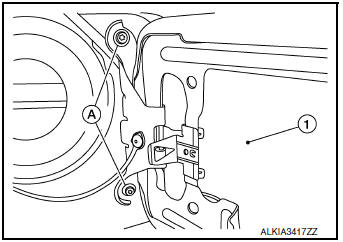

- Remove hood hinge to hood nuts (A) and hood assembly.

NOTE: RH side shown; LH similar.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Before installing the hood hinge, apply anticorrosive agent onto the surface of the vehicle.

- After installation, perform the hood assembly adjustment procedure. Refer to DLK-351, "HOOD ASSEMBLY : Adjustment".

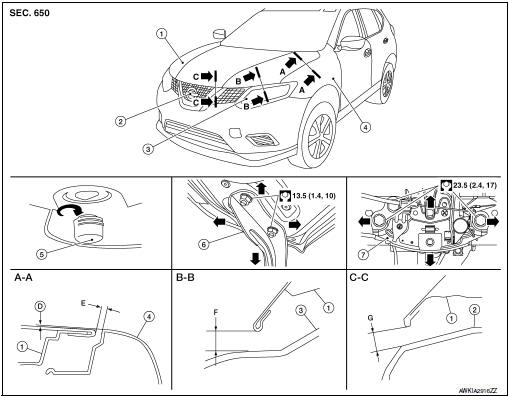

HOOD ASSEMBLY : Adjustment

- Hood assembly

- Front grille

- Front combination lamp

- Fender

- Bumper rubber

- Hood hinge

- Hood lock

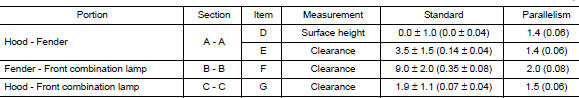

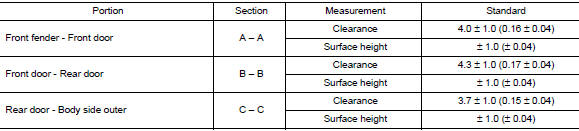

Check the clearance and the surface height between hood and each part by visual inspection and tactile feel.

If the clearance and the surface height are out of specification, adjust them according to the adjustment procedures.

HEIGHT ADJUSTMENT

- Loosen the hood lock assembly bolts.

- Adjust the surface height of hood assembly to front grille and front fender according to the specified values by rotating hood bumper rubber.

- Temporarily tighten hood lock assembly bolts.

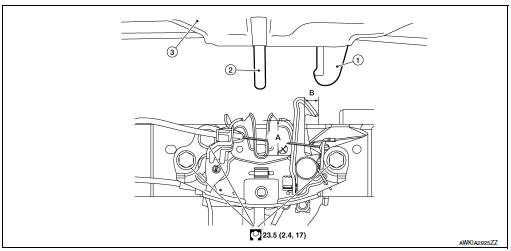

- Adjust (A) and (B) as shown to the following value with hood's own weight by dropping it from approximately 200 mm (7.87 in) height or by pressing hood lightly [approximately 29 N (3.0 kg, 6.5 lb)].

- Secondary striker

- Primary striker

- Hood assembly

- 20 mm (0.79 in)

- 6.8 mm (0.27 in)

- After adjustment, tighten hood hinge nuts and bolts to the specified torque.

CAUTION:

- Check hood hinge rotating part for poor lubrication. If necessary, apply a suitable multi-purpose grease.

- After adjusting, apply touch-up paint (body color) to the head of hood hinge bolts and nuts.

CLEARANCE ADJUSTMENT

- Loosen hood hinge nuts and bolts.

- Loosen the hood lock assembly bolts.

- Adjust the hood assembly so the clearance measurements are within specifications.

- Tighten the hood hinge nuts and bolts to specified torque.

- Tighten the hood lock assembly bolts to specified torque.

HOOD HINGE

HOOD HINGE : Removal and Installation

REMOVAL

- Remove hood assembly. Refer to DLK-350, "HOOD ASSEMBLY : Removal and Installation".

- Remove front fender. Refer to DLK-355, "Removal and Installation".

- Remove hood hinge bolts, and then remove hood hinge.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Before installing the hood hinge, apply anticorrosive agent onto the surface of the vehicle.

- After installation, perform hood assembly adjustment procedure. Refer to DLK-351, "HOOD ASSEMBLY : Adjustment".

RADIATOR CORE SUPPORT

Exploded View

- Radiator core upper support

- Secondary latch bracket

- Radiator core lower support

Removal and Installation

CAUTION: When removing radiator core support upper, be careful not to damage the painted surface.

REMOVAL

Radiator Core Upper Support

- Remove front combination lamp (LH). Refer to EXL-119, "Removal and Installation".

- Remove front air duct. Refer to EM-24, "Exploded View".

- Remove hood lock. Refer to DLK-253, "HOOD LOCK : Removal and Installation".

- Remove secondary latch. Refer to DLK-254, "SECONDARY LATCH : Removal and Installation".

- Remove crash zone sensor. Refer to SR-22, "Removal and Installation".

- Remove bolts and radiator core upper support.

Radiator Core Lower Support

- Remove front bumper fascia. Refer to EXT-17, "Removal and Installation".

- Support the radiator using a suitable tool.

- Remove bolts and radiator core lower support.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION: Tighten bolts to specified torque. Refer to DLK-354, "Exploded View".

FRONT FENDER

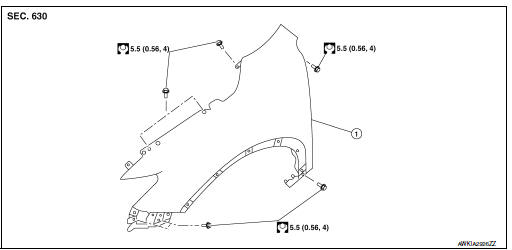

Exploded View

- Front fender

Removal and Installation

CAUTION: Use a shop cloths to protect the body from being damaged during removal and installation.

REMOVAL

- Remove front bumper fascia. Refer to EXT-17, "Removal and Installation".

- Remove front combination lamp. Refer to EXL-119, "Removal and Installation" (HALOGEN HEADLAMP) or EXL-268, "Removal and Installation". (LED HEADLAMP).

- Remove center mudguard. Refer to EXT-42, "Removal and Installation".

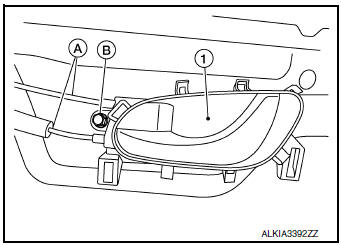

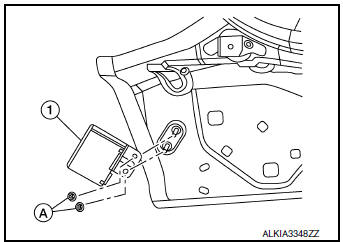

- Remove screws (A) and front fender bracket (1).

- Remove bolts and front fender.

CAUTION: Use care when removing the front fender. The front fender baffle foam adheres the front fender to the body side outer. Carefully release the baffle foam or damage to the front fender may occur.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- After installation apply touch up paint (body color) to the head of front fender bolts.

- After installation, adjust the following components as necessary:

- Hood assembly: Refer to DLK-351, "HOOD ASSEMBLY : Adjustment".

- Front door: Refer to DLK-358, "DOOR ASSEMBLY : Adjustment".

- Tighten bolts to specification. Refer to DLK-355, "Exploded View".

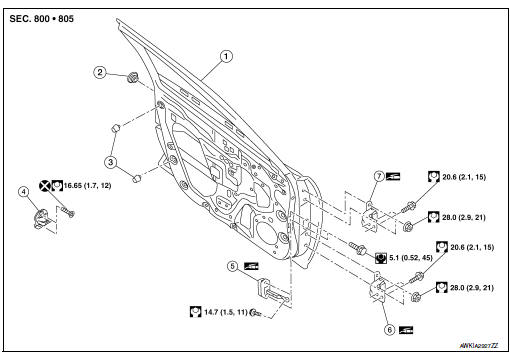

FRONT DOOR

Exploded View

- Front door panel

- Grommet

- Bumper rubber

- Door striker

- Door check link

- Front door lower hinge

- Front door upper hinge

DOOR ASSEMBLY

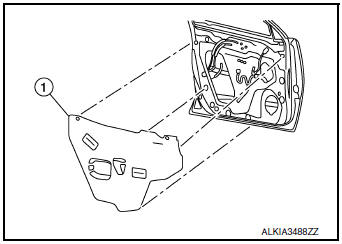

DOOR ASSEMBLY : Removal and Installation

CAUTION:

- Use two people when removing or installing the front door due to its heavy weight.

- When removing and installing front door assembly, support front door with a suitable tool.

REMOVAL

- Remove front door finisher. Refer to INT-15, "Removal and Installation".

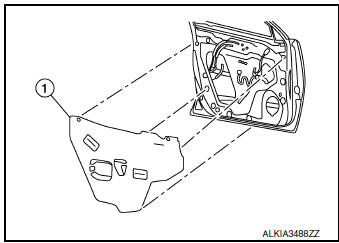

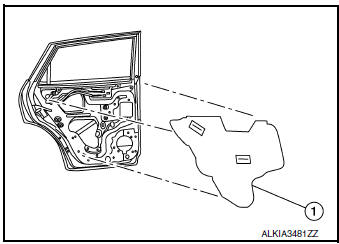

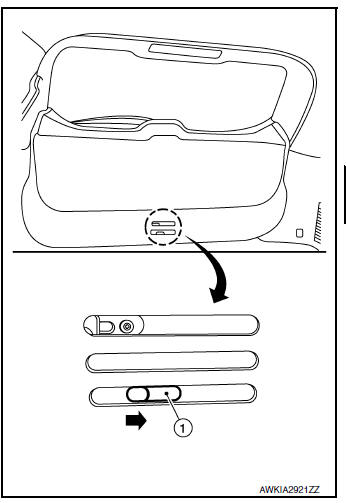

- Remove front door vapor barrier (1).

NOTE: LH side shown; RH similar.

- Disconnect the harness connectors from the front door.

- Remove front door harness grommet, then harness from the front door.

- Remove front door check link bolt (body side).

- Remove front door hinge nuts (door side) and front door assembly.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Tighten nuts/bolts to specified torque. Refer to DLK-357, "Exploded View".

- Apply anticorrosive agent where necessary.

- After installation, check front door open/close and lock/unlock operation.

- After installation, perform the front door adjustment procedure. Refer to DLK-358, "DOOR ASSEMBLY : Adjustment".

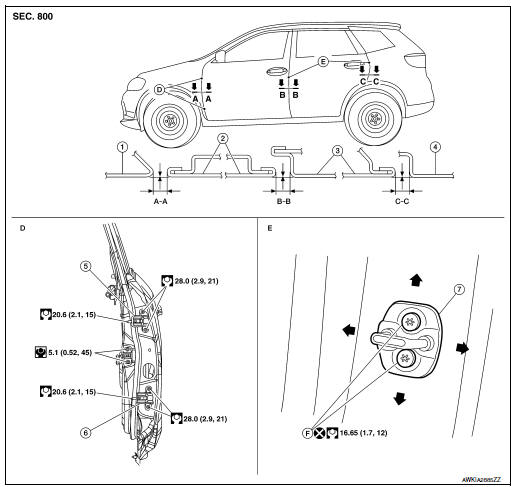

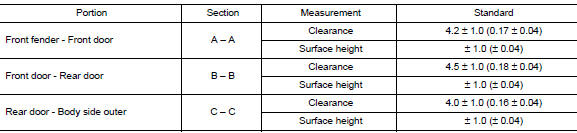

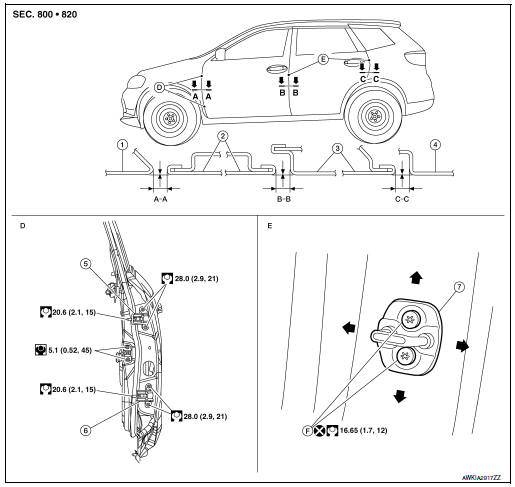

DOOR ASSEMBLY : Adjustment

ADJUSTMENT

- Front fender

- Front door

- Rear door

- Body side outer

- Front door upper hinge

- Front door lower hinge

- Door striker

- Front door striker bolts

Check the clearance and surface height between front door and each part by visual inspection and tactile feel.

If the clearance and the surface height are out of specification, adjust them according to the adjustment procedure.

- Remove front fender. Refer to DLK-355, "Removal and Installation".

- Loosen front door hinge nuts (door side).

- Adjust the surface height of front door according to the specifications provided.

- Temporarily tighten front door hinge nuts (door side).

- Loosen front door hinge bolts (body side).

- Raise front door at rear end to adjust clearance of the front door according to the specifications provided.

- After adjustment tighten bolts and nuts to the specified torque.

CAUTION:

- Check door hinge rotating point for poor lubrication. If necessary, apply a suitable multi-purpose grease.

- After adjusting, apply touch-up paint (body color) to the head of front door hinge bolts and nuts.

- Install front fender. Refer to refer to DLK-355, "Removal and Installation".

DOOR STRIKER

DOOR STRIKER : Removal and Installation

REMOVAL

Remove bolts and front door striker.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not reuse front door striker bolts.

- After installation, check front door open/close operation. If

necessary, adjust the front door striker.

Refer to DLK-359, "DOOR STRIKER : Adjustment".

- Tighten bolts to specified torque. Refer to DLK-357, "Exploded View".

DOOR STRIKER : Adjustment

DOOR STRIKER ADJUSTMENT

- Loosen door striker bolts

- Adjust door striker so that it becomes parallel with front door lock insertion direction.

- Tighten door striker bolts to specification. Refer to DLK-357, "Exploded View".

DOOR HINGE

DOOR HINGE : Removal and Installation

REMOVAL

- Remove front fender. Refer to DLK-355, "Removal and Installation".

- Remove front door assembly. Refer to DLK-357, "DOOR ASSEMBLY : Removal and Installation".

- Remove front door hinge bolts (body side) and front door hinge.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Tighten nuts/bolts to specified torque. Refer to DLK-357, "Exploded View".

- Apply anticorrosive agent to the hinge mating surface.

- After installation, check front door open/close and lock/unlock operation.

- Check door hinge rotating point for poor lubrication. If necessary, apply a suitable multi-purpose grease.

- After installation, perform the front door adjustment procedure. Refer to DLK-358, "DOOR ASSEMBLY : Adjustment".

DOOR CHECK LINK

DOOR CHECK LINK : Removal and Installation

REMOVAL

- Fully close the front door window.

- Remove front door speaker. Refer to AV-67, "Removal and Installation" (DISPLAY AUDIO), AV-213, "Removal and Installation" (NAVIGATION WITHOUT BOSE) or AV-381, "Removal and Installation" (NAVIGATION WITH BOSE).

- Remove door check link bolt (body side).

- Remove door check link bolts (door side).

- Remove door check link through the hole in door assembly.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Tighten nuts/bolts to specified torque. Refer to DLK-357, "Exploded View".

- After installation, check front door open/close and lock/unlock operation.

- Check door check link rotating point for poor lubrication. If necessary, apply a suitable multi-purpose grease.

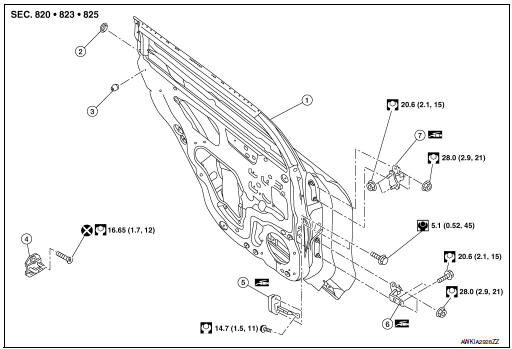

REAR DOOR

Exploded View

- Rear door panel

- Grommet

- Bumper rubber

- Door striker

- Door check link

- Rear door lower hinge

- Rear door upper hinge

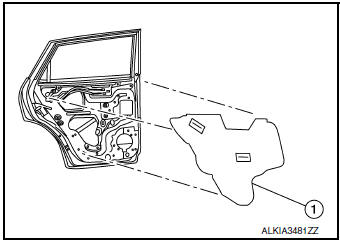

DOOR ASSEMBLY

DOOR ASSEMBLY : Removal and Installation

CAUTION:

- Use two people when removing or installing the rear door due to its heavy weight.

- When removing and installing rear door assembly, support rear door using a suitable tool.

REMOVAL

- Remove rear door finisher. Refer to DLK-361, "DOOR ASSEMBLY : Removal and Installation".

- Remove rear door vapor barrier (1).

NOTE: LH side shown; RH similar.

- Disconnect the harness connectors from rear door.

- Remove harness grommet from rear door, then pull out rear door harness from the rear door.

- Remove rear door check link bolt (body side).

- Remove rear door hinge nuts (door side) and rear door assembly.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Tighten nuts/bolts to specification. Refer to DLK-361, "Exploded View".

- Apply anticorrosive agent where necessary.

- After installation, check rear door open/close and lock/unlock operation.

- After installation, perform the rear door adjustment procedure. Refer to DLK-362, "DOOR ASSEMBLY : Adjustment".

DOOR ASSEMBLY : Adjustment

- Front fender

- Front door

- Rear door

- Body side outer

- Door striker

- Rear door upper hinge

- Rear door lower hinge

- Door striker bolts

Check the clearance and surface height between rear door and each part by visual inspection and tactile feel.

If the clearance and the surface height are out of specification, adjust them according to the adjustment procedures.

- Remove center pillar lower finisher. Refer to INT-22, "CENTER PILLAR LOWER FINISHER : Removal and Installation".

- Loosen rear door hinge nuts (door side).

- Adjust the surface height of rear door according to specifications provided.

- Temporarily tighten rear door hinge nuts (door side).

- Loosen rear door hinge nuts and bolts (body side).

- Raise rear door at rear end to adjust clearance of rear door according to the specifications provided.

- After adjustment tighten bolts and nuts to the specified torque.

CAUTION:

- Check rear door hinge rotating point for poor lubrication. If necessary, apply a suitable multi-purpose grease.

- After adjusting, apply touch-up paint (body color) to the head of rear door hinge bolts and nuts.

- Install center pillar lower finisher. Refer to INT-22, "CENTER PILLAR LOWER FINISHER : Removal and Installation".

DOOR STRIKER

DOOR STRIKER : Removal and Installation

REMOVAL

Remove bolts and rear door striker.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not reuse rear door striker bolts.

- Tighten bolts to specification. Refer to DLK-361, "Exploded View".

- After installation, check rear door open/close operation. If necessary, adjust the door striker. Refer to DLK-363, "DOOR STRIKER : Adjustment".

DOOR STRIKER : Adjustment

DOOR STRIKER ADJUSTMENT

- Loosen door striker bolts

- Adjust door striker so that it becomes parallel with front door lock insertion direction.

- Tighten door striker bolts to specification. Refer to DLK-361, "Exploded View".

DOOR HINGE

DOOR HINGE : Removal and Installation

REMOVAL

- Remove rear door assembly. Refer to DLK-361, "DOOR ASSEMBLY : Removal and Installation".

- Remove center pillar lower finisher (rear door lower hinge only). Refer to INT-22, "CENTER PILLAR LOWER FINISHER : Removal and Installation".

- Remove rear door hinge bolts and nuts and rear door hinge.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Tighten nuts/bolts to specification. Refer to DLK-361, "Exploded View".

- Apply anticorrosive agent onto the hinge mating surface.

- After installation, check rear door open/close and lock/unlock operation.

- After installation, perform the rear door adjustment procedure. Refer to DLK-362, "DOOR ASSEMBLY : Adjustment".

DOOR CHECK LINK

DOOR CHECK LINK : Removal and Installation

REMOVAL

- Fully close the rear door window.

- Remove rear door speaker. Refer to AV-68, "Removal and Installation" (DISPLAY AUDIO), AV-214, "Removal and Installation" (NAVIGATION WITHOUT BOSE) or AV-383, "Removal and Installation" (NAVIGATION WITH BOSE).

- Remove rear door check link bolt (body side).

- Remove rear door check link bolts (door side).

- Remove rear door check link through the hole in rear door panel.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Tighten bolts to specification. Refer to DLK-361, "Exploded View".

- After installation, check rear door open/close and lock/unlock operation.

- Check rear door check link rotating point for poor lubrication. If necessary, apply a suitable multipurpose grease.

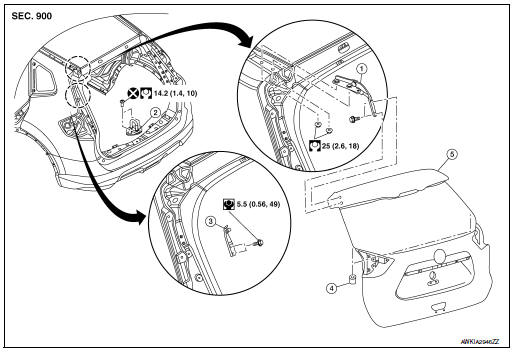

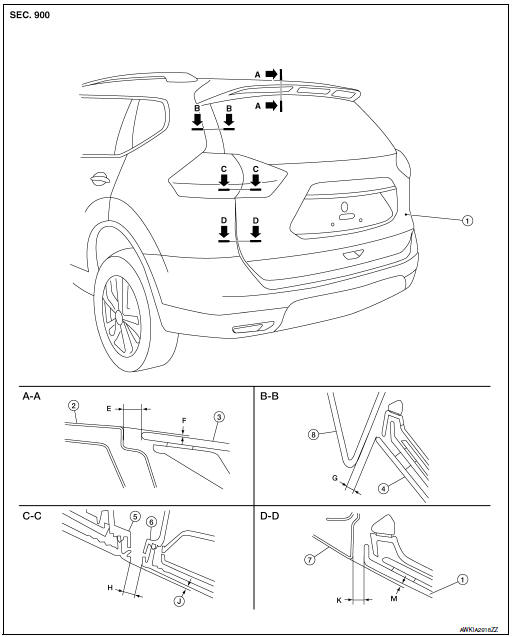

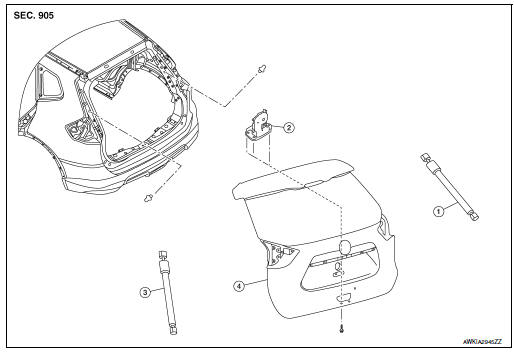

BACK DOOR

Exploded View

- Back door hinge

- Back door striker

- Back door stay hinge

- Bumper rubber

- Back door

BACK DOOR ASSEMBLY

BACK DOOR ASSEMBLY : Removal and Installation

CAUTION:

- Use two people when removing or installing the back door due to its heavy weight.

- Use shop cloths to protect surrounding components from damage during removal and installation of back door.

REMOVAL

- Support the back door assembly using a suitable tool.

WARNING: Bodily injury may occur if back door assembly is not supported properly when removing the back door spindle unit.

- Remove back door stays (LH/RH). Refer to DLK-264, "BACK DOOR STAY : Removal and Installation".

- Remove roof side moldings (LH/RH). Refer to EXT-39, "Removal and Installation".

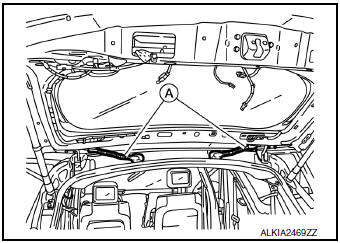

- Disconnect harness connectors (A) from back door.

- Remove back door harness grommet, then pull harness from the back door.

- Disconnect washer tube.

- Remove washer tube grommet and washer tube from the back door.

- Remove back door hinge bolts (door side) and back door assembly.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Tighten bolts to specification. Refer to DLK-365, "Exploded View".

- Apply anticorrosive agent onto the surface between hinge and door side.

- When reusing stud ball, always apply locking sealant before installing stud ball to back door.

- After installation, perform the back door assembly adjustment procedure. Refer to DLK-367, "BACK DOOR ASSEMBLY : Adjustment".

- Perform calibration of automatic back door position information. Refer to DLK-103, "Work Procedure".

BACK DOOR ASSEMBLY : Adjustment

- Back door assembly

- Roof panel

- Rear spoiler

- Back door glass

- Rear combination lamp

- Back-up lamp

- Rear fender

- Side spoiler

Check the clearance and the surface height between back door and each part by visual inspection and tactile feel. If the clearance and the surface height are out of specification, adjust them according to the adjustment procedure.

- Loosen back door hinge nuts (door side).

- Lift up back door approximately 100 – 150 mm (3.94 – 5.91 in) height then close it lightly and check that it is engaged firmly with back door closed.

- Check the clearance and surface height according to the specifications provided.

- Tighten back door hinge nuts to specified torque.

CAUTION:

- After installation, check back door open/close, lock/unlock operation.

- Check back door hinge rotating point for poor lubrication. If necessary, apply a suitable multipurpose grease.

- After adjusting, apply touch-up paint (body color) to the head of rear door hinge bolts and nuts.

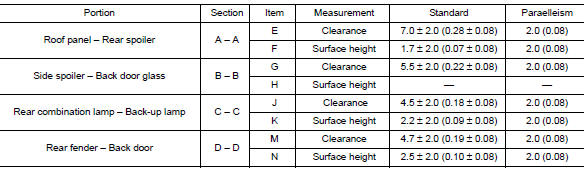

BACK DOOR STRIKER

BACK DOOR STRIKER : Removal and Installation

REMOVAL

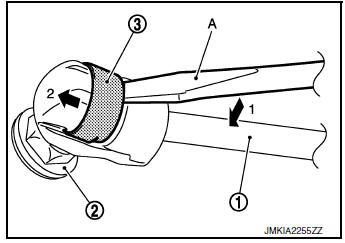

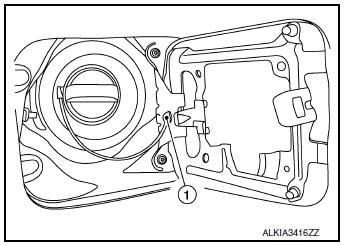

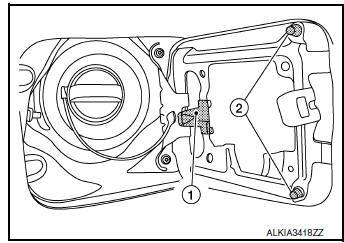

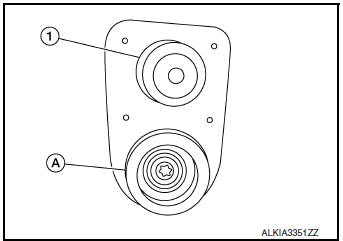

- Release back door striker cover (1) pawls using a suitable tool

and remove.

: Pawl

: Pawl

- Remove bolts and back door striker.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not reuse back door striker bolts.

- Tighten bolts to specification. Refer to DLK-365, "Exploded View".

- After installation, check back door open/close operation. If necessary, adjust the door striker. Refer to DLK-368, "BACK DOOR STRIKER : Adjustment".

BACK DOOR STRIKER : Adjustment

DOOR STRIKER ADJUSTMENT

- Loosen door striker bolts

- Adjust door striker so that it becomes parallel with front door lock insertion direction.

- Tighten door striker bolts to specification. Refer to DLK-365, "Exploded View".

BACK DOOR HINGE

BACK DOOR HINGE : Removal and Installation

REMOVAL

- Remove back door assembly. Refer to DLK-365, "BACK DOOR ASSEMBLY : Removal and Installation".

- Partially remove the rear of the headlining. Refer to INT-30, "Removal and Installation".

- Remove nuts and back door hinge.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Tighten nuts to specification. Refer to DLK-365, "Exploded View".

- Apply anticorrosive agent onto the surface between hinge and body side.

- After installation, perform the back door assembly adjustment procedure. Refer to DLK-367, "BACK DOOR ASSEMBLY : Adjustment".

BACK DOOR WEATHER-STRIP

BACK DOOR WEATHER-STRIP : Removal and Installation

REMOVAL

Carefully remove back door weather-strip from opening door joint.

INSTALLATION

- Beginning with upper section, align weather-strip mark with vehicle center position mark and install weather strip to the vehicle.

- For the lower section, align weather-strip seam with center of

back door striker.

NOTE: Pull weather-strip gently to ensure that there are no loose sections.

HOOD LOCK

Exploded View

- Hood lock release handle

- Hood lock release cable

- Hood lock

- Secondary latch

- Clip

HOOD LOCK

HOOD LOCK : Removal and Installation

REMOVAL

- Disconnect hood lock release cable and secondary latch cable from hood lock.

- Remove bolts and hood lock.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Tighten bolts to specified torque. Refer to DLK-370, "Exploded View".

- Check that hood lock release cable and secondary latch cable are properly engaged with hood lock.

- After installation, perform hood assembly adjustment procedure. Refer to DLK-351, "HOOD ASSEMBLY : Adjustment".

- After adjusting, perform hood lock inspection. Refer to DLK-370, "HOOD LOCK : Inspection".

HOOD LOCK : Inspection

NOTE: If the hood lock cable is bent or deformed, replace it.

- Check that secondary latch is properly engaged with secondary striker with hoods own weight.

- While operating hood lock release handle, carefully check that the front end of hood assembly is raised by approximately 20.0 mm (0.79 in). Also check that hood lock release handle returns to the original position.

- Check that hood lock release handle operates at 49 N (5.0 kg-m, 11.0 ft-lb) or below.

- Install so that static closing force of hood is 315-490 N (32.1-50.0 kg–m, 70.8-110.2 ft–lb).

NOTE:

- Do not exert vertical force on right side and left side of hood lock.

- Do not press simultaneously on both sides.

- Check the hood lock lubrication condition. If necessary, apply a suitable multi-purpose grease to hood lock assembly.

SECONDARY LATCH

SECONDARY LATCH : Removal and Installation

REMOVAL

- Remove front grille. Refer to EXT-23, "Removal and Installation".

- Disconnect secondary latch cable from hood lock assembly.

- Remove bolts and secondary latch.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Tighten bolts to specified torque. Refer to DLK-370, "Exploded View".

- Check that secondary latch cable is properly engaged with hood lock.

HOOD LOCK RELEASE CABLE

HOOD LOCK RELEASE CABLE : Removal and Installation

REMOVAL

- Remove fender protector (LH). Refer to EXT-28, "FENDER PROTECTOR : Removal and Installation".

- Remove front grille. Refer to EXT-23, "Removal and Installation".

- Disconnect hood lock release cable from hood lock release handle and hood lock.

- Release hood lock release cable clips using a suitable tool.

- Remove grommet on the lower dash and carefully pull the hood lock release cable into the passenger compartment.

CAUTION: While pulling, be careful not to damage (peel) the outside of hood lock release cable.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Be careful not to bend cable too much, keep the radius 100 mm (3.94 in) or more.

- Check that cable is not offset from the positioning grommet, and apply the sealant to the grommet (at * mark) properly.

- Check that hood lock release cable is properly engaged with hood lock assembly.

- After installation, perform hood assembly adjustment procedure. Refer to DLK-351, "HOOD ASSEMBLY : Adjustment".

- After adjusting, perform hood lock inspection. Refer to DLK-370, "HOOD LOCK : Inspection".

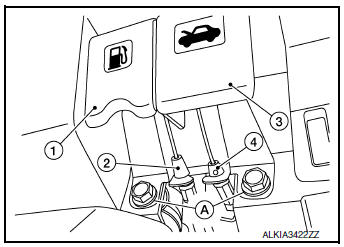

HOOD LOCK RELEASE HANDLE

HOOD LOCK RELEASE HANDLE : Removal and Installation

REMOVAL

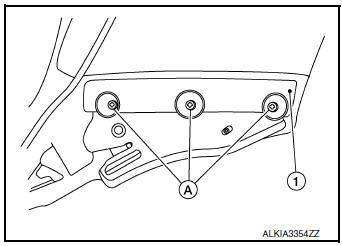

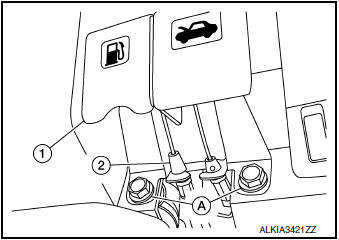

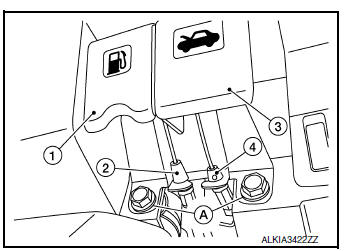

- Remove fuel filler lid/hood lock release handle bolts (A).

- Disconnect fuel filler lid release cable (2) from fuel filler lid release handle (1).

- Disconnect hood lock release cable (4) from hood lock release handle (3).

- Remove hood lock release handle.

INSTALLATION

Installation is in the reverse order of removal.

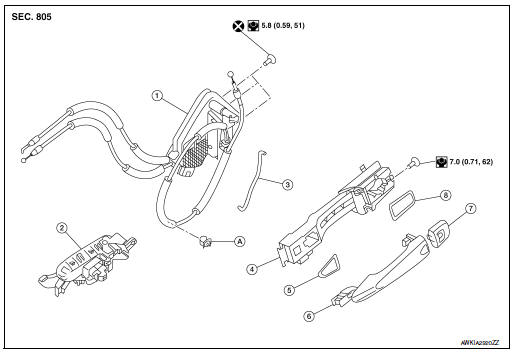

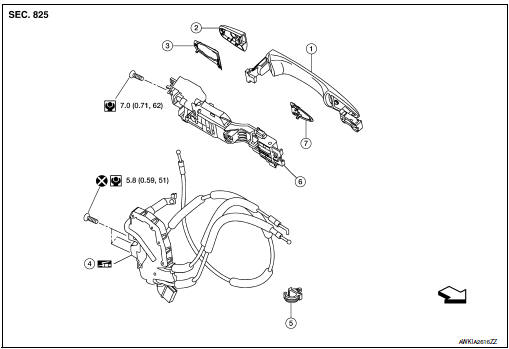

FRONT DOOR LOCK

Exploded View

- Front door lock

- Inside handle

- Door key cylinder rod (LH only)

- Outside handle bracket

- Front gasket

- Outside handle

- Outside handle escutcheon / door key cylinder (LH only)

- Rear gasket

- Clip

DOOR LOCK

DOOR LOCK : Removal and Installation

REMOVAL

- Remove front door finisher. Refer to INT-15, "Removal and Installation".

- Remove vapor barrier.

- Remove front door lock bolts (A).

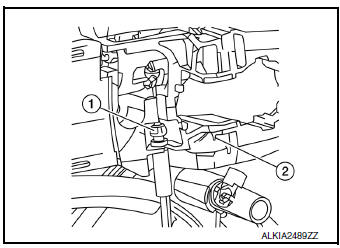

- Disconnect door key cylinder rod (LH only) (1) from front door lock (2) (LH only).

- Disconnect door lock cables from inside handle and outside handle..

- Disconnect the harness connector from the front door lock and remove.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not reuse front door lock bolts.

- Tighten bolts to specification. Refer to DLK-373, "Exploded View".

- After installation, check door lock cables are properly engaged to inside handle and outside handle bracket.

- When installing door key cylinder rod (LH only), be sure to rotate door key cylinder rod holder until a click is felt.

- After installation, check door open/close and lock/unlock operation.

- Check door lock assembly for poor lubrication. If necessary apply a suitable multi-purpose grease.

INSIDE HANDLE

INSIDE HANDLE : Removal and Installation

REMOVAL

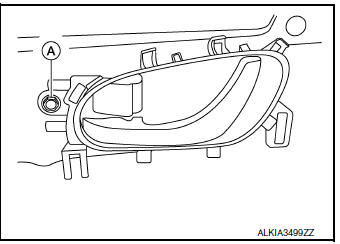

- Remove front door finisher. Refer to INT-15, "Removal and Installation".

- Remove inside handle bolt (B).

- Disconnect the door lock cables (A) and remove inside handle (1).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- After installation, check door lock cables are properly engaged to inside handle.

- After installation, check door open/close and lock/unlock operation.

OUTSIDE HANDLE

OUTSIDE HANDLE : Removal and Installation

REMOVAL

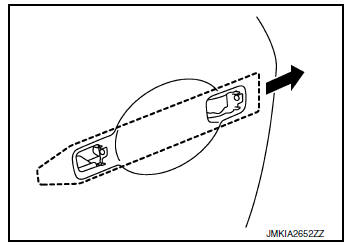

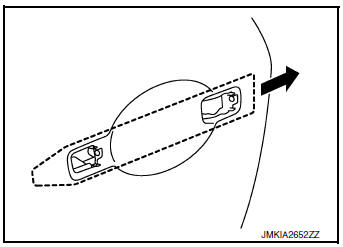

- Fully close front door glass.

- Remove front door finisher. Refer to INT-15, "Removal and Installation".

- Remove front door vapor barrier (1).

NOTE: LH side shown; RH similar.

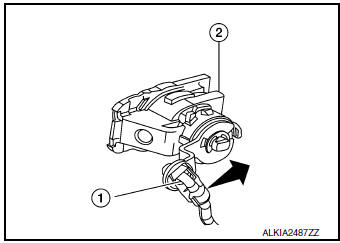

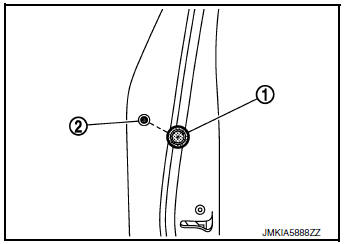

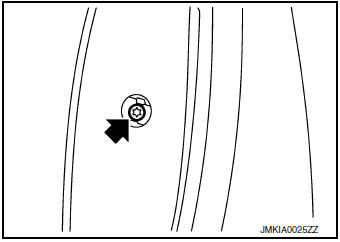

- Remove door side grommet (1), and remove bolt from grommet hole (2).

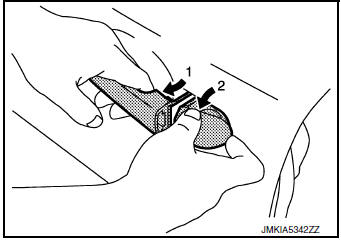

- Separate door key cylinder rod (LH only) (1) from door key cylinder assembly (LH only) (2).

- While pulling (1) outside handle, remove (2) door key cylinder assembly (LH side) or outside handle escutcheon (RH side).

- While pulling outside handle (1), slide toward rear of vehicle to remove outside handle.

- Remove front gasket and rear gasket.

- Slide outside handle bracket toward rear of vehicle to remove.

- Disconnect outside handle cable (1) from outside handle bracket (2) as shown.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- When installing door key cylinder rod (LH only), be sure to rotate door key cylinder rod holder until a click is felt.

- After installation, check door lock cable is properly engaged to outside handle bracket.

- After installation, check door open/close and lock/unlock operation.

REAR DOOR LOCK

Exploded View

- Outside handle

- Outside handle escutcheon

- Rear gasket

- Rear door lock

- Cable clip

- Outside handle bracket

- Front gasket

Front

Front

DOOR LOCK

DOOR LOCK : Removal and Installation

REMOVAL

- Remove rear door finisher. Refer to INT-18, "Removal and Installation".

- Remove vapor barrier.

- Remove rear door lock bolts.

- Disconnect the door lock cables.

- Disconnect the harness connector from the rear door lock and remove.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not reuse rear door lock bolts.

- Tighten bolts to specification. Refer to DLK-377, "Exploded View".

- After installation, check door lock cables are properly engaged to inside handle and outside handle.

- After installation, check door open/close and lock/unlock operation.

INSIDE HANDLE

INSIDE HANDLE : Removal and Installation

REMOVAL

- Remove rear door finisher. Refer to INT-18, "Removal and Installation".

- Remove inside handle bolt (A).

- Disconnect door lock cables from inside handle and remove.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- After installation, check door lock cables are properly engaged to inside handle.

- After installation, check door open/close and lock/unlock operation.

OUTSIDE HANDLE

OUTSIDE HANDLE : Removal and Installation

REMOVAL

- Fully close rear door glass.

- Remove rear door finisher. Refer to INT-18, "Removal and Installation".

- Remove rear door vapor barrier (1).

NOTE: LH side shown; RH similar.

- Remove door side grommet and bolt from grommet hole.

- While pulling (1) outside handle, remove (2) outside handle escutcheon.

- While pulling outside handle (1), slide toward rear of vehicle to remove outside handle.

- Remove front gasket and rear gasket.

- Slide outside handle bracket toward rear of vehicle to remove.

- Disconnect outside handle cable (1) from outside handle bracket (2) as shown.

INSTALLATION

Installation in the reverse order of removal.

CAUTION:

- After installation, check door lock cable is properly engaged to outside handle bracket.

- After installation, check door open/close and lock/unlock operation.

BACK DOOR LOCK

Exploded View

- Back door stay (RH)

- Back door lock

- Back door stay (LH)

- Back door

DOOR LOCK

DOOR LOCK : Removal and Installation

REMOVAL

- Remove back door finisher. Refer to INT-38, "Removal and Installation".

- Disconnect the harness connector from the back door lock.

- Remove bolts and back door lock.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Tighten bolts to specification. Refer to DLK-380, "Exploded View".

- After installation, check back door open/close and lock/unlock operation.

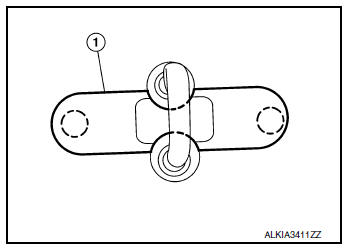

BACK DOOR STAY

BACK DOOR STAY : Removal and Installation

REMOVAL

- Support the back door using a suitable tool.

WARNING: Body injury may occur if no supporting rod is holding the back door open when removing the back door stay.

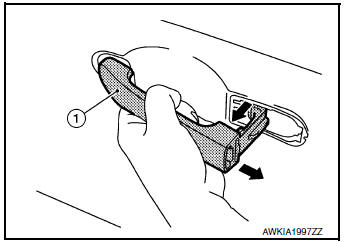

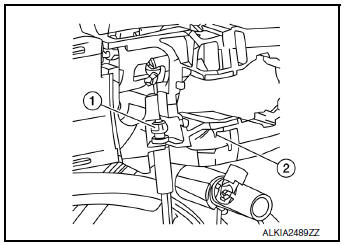

- Releaase the metal clip (3) located on the connection between the back door stay (1) and the stud ball (2) (back door side) using a suitable tool (A).

- Remove the back door stay (back door side).

- Repeat procedure for removing back door stay from body side.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION: After installation, check the back door open/close operation.

EMERGENCY LEVER

EMERGENCY LEVER : Unlock procedures

UNLOCK PROCEDURES

NOTE: If back door lock cannot be unlocked due to a malfunction or battery discharge, perform the following procedures to unlock back door assembly.

- From inside the vehicle, rotate emergency lever (1) in the direction shown to unlock.

FUEL FILLER LID OPENER

Exploded View

- Fuel filler lid release cable

- Fuel filler lid release handle

- Spring

- Bumper rubber

- Fuel filler lid lock

- Screw

FUEL FILLER LID

FUEL FILLER LID : Removal and Installation

REMOVAL

- Remove fuel cap pin (1).

- Remove screws(2) and fuel filler lid (1).

- Remove fuel filler lid spring (1) and bumper rubber (2) from fuel filler lid (if necessary).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION: After installation, check fuel filler lid open/close, lock/unlock operation.

FUEL FILLER LID LOCK

FUEL FILLER LID LOCK : Removal and Installation

REMOVAL

- Remove luggage side lower finisher (RH). Refer to INT-34, "LUGGAGE SIDE LOWER FINISHER : Removal and Installation - With Third Row Seat" (With Third Row Seat) or INT-35, "LUGGAGE SIDE LOWER FINISHER : Removal and Installation - Without Third Row Seat" (Without Third Row Seat).

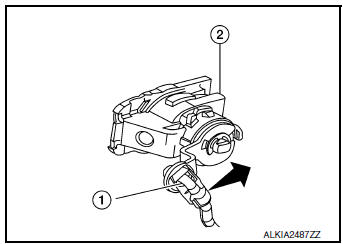

- Disconnect the fuel filler lid release cable (1) from the fuel filler lid lock (2).

- Rotate fuel filler lid lock to release pawls and remove.

: Pawl

INSTALLATION

Installation is in the reverse order of removal.

CAUTION: After installation, check fuel filler lid open/close, lock/unlock operation.

FUEL FILLER LID RELEASE CABLE

FUEL FILLER LID RELEASE CABLE : Removal and Installation

REMOVAL

- Partially remove front floor trim. Refer to INT-26, "Removal and Installation".

- Remove rear floor trim. Refer to INT-26, "Removal and Installation".

- Remove the fuel filler lid/hood lock release handle bolts (A)

- Disconnect the fuel filler lid release cable (2) from fuel filler lid release handle (1).

- Disconnect the fuel filler lid release cable (1) from fuel filler lid lock (2).

- Release the clips and remove fuel filler lid release cable.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION: After installation, check fuel filler lid open/close, lock/unlock operation.

FUEL FILLER LID RELEASE HANDLE

FUEL FILLER LID RELEASE HANDLE : Removal and Installation

REMOVAL

- Remove fuel filler lid/hood lock release handle bolts (A).

- Disconnect fuel filler lid release cable (2) from fuel filler lid release handle (1).

- Disconnect hood lock release cable (4) from hood lock release handle (3).

- Remove fuel filler lid release handle.

INSTALLATION

Installation is in the reverse order of removal.

DOOR SWITCH

Removal and Installation

REMOVAL

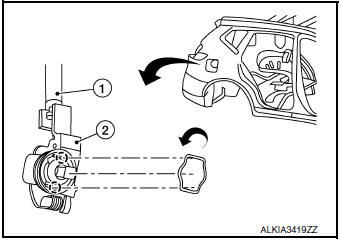

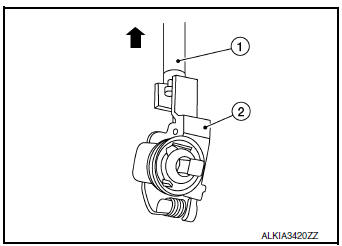

- Remove the door switch bolt (A).

- Disconnect the harness connector from the door switch (1) and remove.

INSTALLATION

Installation is in the reverse order of removal.

BACK DOOR WARNING CHIME

Removal and Installation

- REMOVAL Remove the rear bumper fascia. Refer to EXT-20, "Removal and Installation".

- Disconnect the harness connector from the back door warning chime.

- Remove nuts (A) and back door warning chime (1).

INSTALLATION

Installation is in the reverse order of removal.

KEYFOB BATTERY

Removal and Installation

REPLACEMENT

- Remove screw from the rear of keyfob.

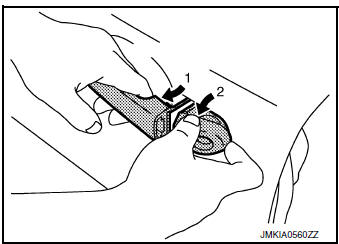

- Place the key with the lower case facing up. Use a suitable tool wrapped with tape between upper case and lower case and separate the lower case from the upper case.

CAUTION:

- Do not touch the circuit board or battery terminal. Doing so could cause the keyfob to malfunction

- The keyfob is water-resistant. However, if it does get wet, immediately wipe it dry.

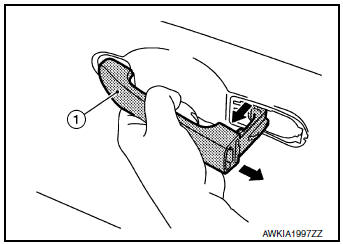

- When replacing the circuit board assembly, remove circuit board

assembly from the upper case.

[Circuit board assembly: Switch rubber + Board surface] CAUTION: Do not touch the printed circuits directly.

- Remove the battery from the lower case and replace it.

Battery replacement : Coin-type lithium battery (CR1620)

CAUTION: When replacing battery, keep dirt, grease, and other foreign materials off the electrode contact area.

- After replacement, fit the lower and upper cases together and tighten with the screw.

CAUTION: After replacing the battery, Be sure to check that door locking operates normally using the keyfob.

Refer to DLK-333, "Component Function Check".

Symptom diagnosis

Symptom diagnosis

POWER DOOR LOCK SYSTEM SYMPTOMS

Symptom Table

DOOR LOCK/UNLOCK FUNCTION MALFUNCTION

NOTE:

Before performing the diagnosis in the following table, check

“WORK FLOW”. Refer to DLK-31 ...

Other materials:

U1000 CAN COMM CIRCUIT

Description

CAN communication allows a high rate of information transmission through the

two communication lines

(CAN-H line and CAN-L line) connecting various control units in the system. Each

control unit transmits/

receives data but selectively reads required data only.

DTC Logic

DTC DET ...

P050A, P050B, P050E cold start control

Description

ECM controls ignition timing and engine idle speed when engine is started

with pre-warming up condition.

This control promotes the activation of three way catalyst by heating the

catalyst and reduces emissions.

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT scre ...

Fuel recommendation

Use unleaded regular gasoline with an octane

rating of at least 87 AKI (Anti-Knock Index) number

(Research octane number 91).

CAUTION

Only vehicles with the E-85 filler door

label can operate on E-85. Fuel system

or other damage can occur if E-85 is

used in vehicles t ...