Nissan Rogue Service Manual: Basic inspection

DIAGNOSIS AND REPAIR WORKFLOW

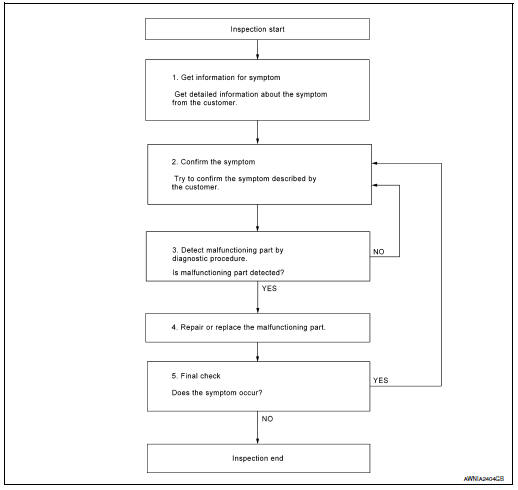

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.GET INFORMATION FOR SYMPTOM

Get detailed information from the customer about the symptom (the condition and the environment when the incident/malfunction occurred).

>> GO TO 2.

2.CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer. Verify relation between the symptom and the condition when the symptom is detected. Refer to AV-59, "Symptom Table".

>> GO TO 3.

3.DETECT MALFUNCTIONING PART BY DIAGNOSTIC PROCEDURE

Inspect according to Diagnostic Procedure of the system.

Is malfunctioning part detected? YES >> GO TO 4.

NO >> GO TO 2.

4.REPAIR OR REPLACE THE MALFUNCTIONING PART

- Repair or replace the malfunctioning part.

- Reconnect parts or connectors disconnected during Diagnostic Procedure.

>> GO TO 5.

5.FINAL CHECK

Refer to confirmed symptom in step 2, and make sure that the symptom is not detected.

Was the repair confirmed? YES >> Inspection End.

NO >> GO TO 2.

Wiring diagram

Wiring diagram

DISPLAY AUDIO

Wiring Diagram

...

DTC/circuit diagnosis

DTC/circuit diagnosis

POWER SUPPLY AND GROUND CIRCUIT

AUDIO UNIT

AUDIO UNIT : Diagnosis Procedure

Regarding Wiring Diagram information, refer to AV-27, "Wiring Diagram".

1.CHECK FUSE

Check that the following ...

Other materials:

Rear wiper and washer system

Wiring Diagram

...

Cluster lid C

Exploded View

Audio unit (AUDIO WITHOUT BOSE) /

AV control unit (AUDIO WITH BOSE)

(NAVIGATION WITH BOSE)

A/C switch assembly (AUTOMATIC

AIR CONDITIONING) / front air control

(MANUAL AIR CONDITIONING)

Cluster lid C

Removal and Installation

REMOVAL

Release ...

Plug

Description

Replace the O-ring if oil leakage or exudes from the plug.

Exploded View

Transaxle assembly

O-ring

Plug

: Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

: Apply CVT fluid

Removal and Installation

REMOVAL

Partially remove front fender prote ...