Nissan Rogue Service Manual: P0197, P0198 EOT sensor

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition |

| P0197 | EOT SEN/CIRC (Engine oil temperature sensor low) | An excessively low voltage from the engine oil temperature sensor is sent to ECM. |

| P0198 | EOT SEN/CIRC (Engine oil temperature sensor high) | An excessively high voltage from the engine oil temperature sensor is sent to ECM. |

POSSIBLE CAUSE

- Harness or connectors (EOT sensor circuit is open or shorted.)

- Engine oil temperature sensor

FAIL-SAFE

Exhaust valve timing control does not function.

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

- Start engine and wait at least 5 seconds.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-281, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

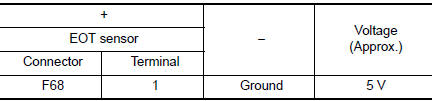

1.CHECK ENGINE OIL TEMPERATURE SENSOR POWER SUPPLY

- Turn ignition switch OFF.

- Disconnect engine oil temperature (EOT) sensor harness connector.

- Turn ignition switch ON.

- Check the voltage between EOT sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

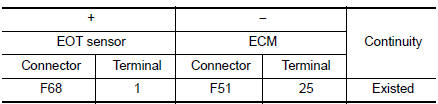

2.CHECK ENGINE OIL TEMPERATURE SENSOR POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between EOT sensor harness connector and ECM harness connector.

- Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

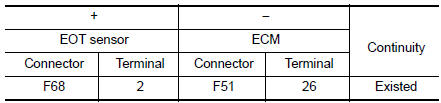

3.CHECK EOT SENSOR GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between EOT sensor harness connector and ECM harness connector.

- Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK ENGINE OIL TEMPERATURE SENSOR

Check the engine oil temperature sensor. Refer to EC-279, "Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace engine oil temperature sensor. Refer to EC-14, "Component Parts Location".

5.CHECK INTERMITTENT INCIDENT

Refer to GI-41, "Intermittent Incident".

>> INSPECTION END

Component Inspection

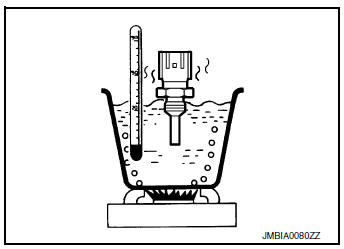

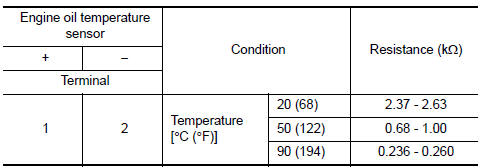

1.CHECK ENGINE OIL TEMPERATURE SENSOR

- Turn ignition switch OFF.

- Disconnect engine oil temperature sensor harness connector.

- Remove engine oil temperature sensor.

- Check resistance between engine oil temperature sensor terminals by heating with hot water as shown in the figure.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace engine oil temperature sensor. Refer to EC-14, "Component Parts Location".

P0196 EOT sensor

P0196 EOT sensor

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0196

EOT SENSOR

(Engine oil temperature sensor ra ...

P0222, P0223 TP sensor

P0222, P0223 TP sensor

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0222

TP SEN 1/CIRC-B1

(Throttle/pedal position se ...

Other materials:

Automatic Anti-glare rearview mirror

(if so equipped)

Automatic Anti-glare rearview mirror

(if so equipped)

The inside mirror is designed so that it automatically

dims during night time conditions and according

to the intensity of the headlights of the

vehicle following you. The automatic anti-glare

feature is activated when the ignition swit ...

Camshaft valve clearance

Camshaft valve clearance

Perform this inspection as follows after removal, installation, or

replacement of the camshaft or any valve

parts, or if there are any unusual engine conditions due to changes in valve

clearance over time (starting,

idling, and/or noise).

Remove the ...

Warning/indicator lights

Warning

light

Name

Anti-lock Braking

System (ABS) warning

light

Brake warning light

Charge warning

light

Low tire pressure

warning light

Low windshield

washer fluid warning

light

Master w ...