Nissan Rogue Service Manual: Engine oil

Inspection

ENGINE OIL LEVEL

NOTE: Before starting engine, put vehicle horizontally and check the engine oil level. If engine is already started, stop it and allow 5 minutes before checking.

- Pull out oil level gauge and wipe it clean.

- Insert oil level gauge and check the engine oil level is within the range (A) as shown.

- If it is out of range, adjust it.

ENGINE OIL APPEARANCE

- Check engine oil for white milky appearance or excessive contamination.

- If engine oil becomes turbid and white, it is highly probable that

it is contaminated with engine coolant.

Repair or replace damaged parts.

ENGINE OIL LEAKS

Check for engine oil leaks around the following areas:

- Oil temperature sensor

- Oil level sensor

- Oil level gauge assembly O-ring.

- Crankshaft position sensor

- Camshaft position sensors

- Oil cooler

- Oil pan (upper and lower)

- Oil pan drain plug

- Oil pressure switch

- Oil filter

- Intake valve timing intermediate lock control solenoid valve

- Intake valve timing control solenoid valve

- Exhaust valve timing control solenoid valve

- Front cover

- Mating surface between cylinder head and camshaft bracket

- Mating surface between cylinder block and cylinder head

- Mating surface between cylinder head and rocker cover

- Crankshaft oil seals (front and rear)

OIL PRESSURE CHECK

WARNING:

- Be careful not to get burn yourself, as engine oil may be hot.

- When checking engine oil pressure, CVT shift lever should be in "P" position. Be sure to apply parking brake.

- Check the engine oil level.

- Remove fender protector side cover (RH). Refer to EXT-28, "FENDER PROTECTOR : Exploded View".

- Disconnect harness connector at oil pressure switch and remove oil

pressure switch using suitable tool.

CAUTION: Never drop or shock oil pressure switch.

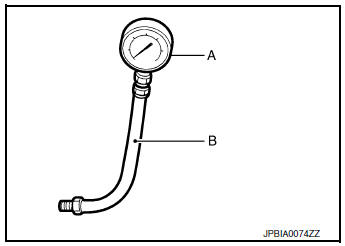

- Install suitable tools (A/B).

- Start the engine and warm it up to normal operating temperature.

- Check the engine oil pressure with engine running under no-load.

NOTE:

- When engine oil temperature is low, engine oil pressure becomes high.

- If difference is extreme, check oil passage and oil pump for engine oil leaks.

Engine oil pressure : Refer to LU-17, "Oil Pressure".

- After the inspections, install oil pressure switch as follows:

- Remove old liquid gasket adhering to oil pressure switch and engine.

- Apply liquid gasket and tighten oil pressure switch to the

specification.

Use Genuine RTV Silicone Sealant or equivalent. Refer to GI-22, "Recommended Chemical Products and Sealants".

Tightening torque : Refer to EM-92, "Exploded View".

- Check engine oil level.

- After warming up engine, check that there are no engine oil leaks with the engine running.

- Install fender protector side cover (RH). Refer to EXT-28, "FENDER PROTECTOR : Exploded View".

Draining

WARNING:

- Be careful not to get burn yourself, as engine oil may be hot.

- Prolonged and repeated contact with used engine oil may cause skin cancer. Try to avoid direct skin contact with used engine oil. If skin contact is made, wash thoroughly with soap or hand cleaner as soon as possible.

- Warm up the engine, and check for engine oil leaks from engine components. Refer to LU-7, "Inspection".

- Stop the engine and wait for 10 minutes.

- Loosen oil filler cap.

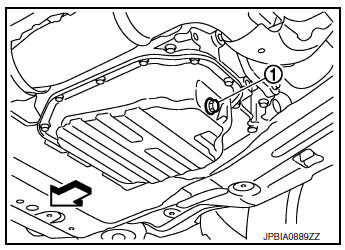

- Remove drain plug (1) and then drain engine oil.

: Front

: Front

Refilling

- Install drain plug with new drain plug washer. Refer to EM-32, "Exploded

View".

CAUTION: Be sure to clean drain plug and install with new drain plug washer.

Tightening torque : Refer to EM-32, "Exploded View".

- Refill with new engine oil.

Engine oil specification and viscosity: Refer to MA-11, "Engine Oil Recommendation".

Engine oil capacity : Refer to LU-17, "Oil Capacity".

CAUTION:

- The refill capacity depends on the engine oil temperature and drain time. Use these specifications for reference only.

- Always use oil level gauge to determine the proper amount of engine oil in engine.

- Warm up the engine and check area around drain plug and oil filter for engine oil leaks.

- Stop the engine and wait for 5 minutes.

- Check the engine oil level. Refer to LU-7, "Inspection".

Oil filter

Oil filter

Removal and Installation

REMOVAL

Remove fender protector side cover (RH). Refer to EXT-28, "FENDER

PROTECTOR : Exploded View".

Drain engine oil. Refer to LU-8, "Dr ...

Other materials:

Controls

Fan control dial

The fan control dial turns the fan on and off, and

controls fan speed.

Air flow control buttons

The air flow control buttons allow you to select

the air flow outlets.

MAX A/C — Air flows mainly from center and

side vents with maximum cooling

and turns on.

— Air flows m ...

Symptom diagnosis

EXTERIOR LIGHTING SYSTEM SYMPTOMS

Symptom Table

CAUTION:

Perform the self-diagnosis with CONSULT before the symptom diagnosis. Perform

the trouble diagnosis

if any DTC is detected.

NORMAL OPERATING CONDITION

Description

AUTO LIGHT SYSTEM

The headlamp may not be turned ON/OFF immedi ...

Preparation

Special Service Tool

The actual shape of the tools may differ from those illustrated here.

Tool number

(TechMate No.)

Tool name

Description

—

(J-39570)

Chassis Ear

Locating the noise

—

(J-46534)

Trim Tool Set

Removing ...