Nissan Rogue Service Manual: C1101, C1102, C1103, C1104 wheel sensor

DTC Logic

DTC DETECTION LOGIC

| DTC | Display Item | Malfunction detected condition | Possible causes |

| C1101 | RR RH SENSOR-1 |

|

|

| C1102 | RR RH SENSOR-1 |

|

|

| C1103 | RR RH SENSOR-1 |

|

|

| C1104 | FR LH SENSOR-1 |

|

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT

With CONSULT.

With CONSULT.

- Start engine and drive vehicle at approximately 21 km/h (13 MPH) or more for approximately 5 minutes.

- Perform self-diagnostic result.

Is DTC C1101, C1102, C1103 or C1104 detected? YES >> Proceed to diagnosis procedure. Refer to BRC-74, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to BRC-57, "Wiring Diagram".

1.CONFIRM DTC

With CONSULT

With CONSULT

- Perform self-diagnostic result of “ABS” and record all active DTCs.

- Clear all DTCs.

- Perform DTC confirmation procedure. Refer to BRC-74, "DTC Logic".

Does DTC C1101, C1102, C1103 or C1104 reset? YES >> GO TO 2.

NO >> Refer to GI-41, "Intermittent Incident".

2.INSPECT WHEEL SENSOR

Inspect the suspect wheel sensor for damage or deformation.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace as necessary.

3.HARNESS AND CONNECTOR INSPECTION

- Disconnect ABS actuator and electric unit (control unit) connector E125 and wheel sensor connector of suspect wheel.

- Check harness, connectors and terminals for corrosion, deformation, disconnection, looseness or damage.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace as necessary.

4.CHECK WHEEL SENSOR OUTPUT SIGNAL

- Connect ABS active wheel sensor tester (J-45741) to wheel sensor using appropriate adapter.

- Turn on the ABS active wheel sensor tester power switch.

NOTE: The green POWER indicator should illuminate. If the POWER indicator does not illuminate, replace the battery in the ABS active wheel sensor tester before proceeding.

- Spin the wheel of the vehicle by hand and observe the red SENSOR indicator on the ABS active wheel sensor tester. The red SENSOR indicator should flash ON and OFF to indicate an output signal.

NOTE: If the red SENSOR indicator illuminates but does not flash, reverse the polarity of the tester leads and retest.

Does the ABS active wheel sensor tester detect a signal? YES >> GO TO 5.

NO >> Replace the wheel sensor. Refer to BRC-132, "FRONT WHEEL SENSOR : Removal and Installation" or BRC-134, "REAR WHEEL SENSOR : Removal and Installation".

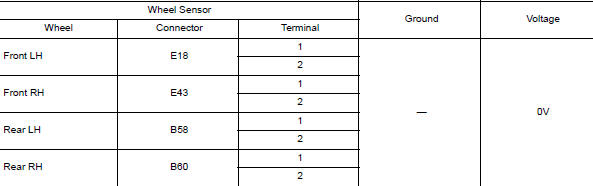

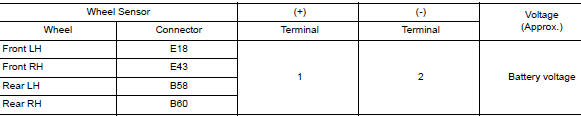

5.CHECK WIRING HARNESS FOR SHORT TO VOLTAGE

- Turn ignition switch ON.

- Check voltage between wheel sensor harness connector terminals of suspect wheel and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair the circuit.

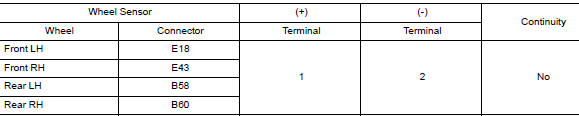

6.CHECK WIRING HARNESS FOR SHORT TO GROUND

- Turn ignition switch OFF.

- Check continuity between wheel sensor harness connector terminals of suspect wheel and ground.

Is the inspection result normal? YES >> GO TO 7.

NO >> Repair the circuit.

7.CHECK WIRING HARNESS FOR SHORT BETWEEN CIRCUITS

Check continuity between wheel sensor harness connector terminals of suspect wheel.

Is the inspection result normal? YES >> GO TO 8.

NO >> Repair the circuit.

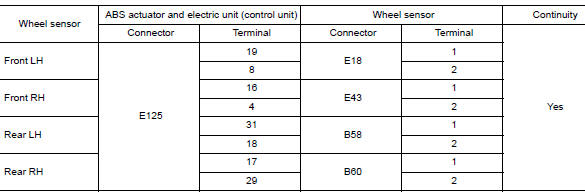

8.CHECK WIRING HARNESS FOR OPEN CIRCUIT

Check continuity between ABS actuator and electric unit (control unit) harness connector E125 and harness connector of suspect wheel sensor.

Is the inspection result normal? YES >> GO TO 9.

NO >> Repair the circuit.

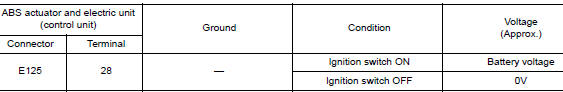

9.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) POWER SUPPLY CIRCUIT

- Turn ignition switch ON.

- Check voltage between ABS actuator and electric unit (control unit) harness connector E125 terminal and ground.

Is the inspection result normal? YES >> GO TO 10.

NO >> Check the following:

- 10A fuse No. 21 located in the FUSE BLOCK (J/B)

- Harness between ABS actuator and electric unit (control unit) and IPDM E/R

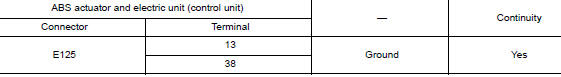

10.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) GROUND CIRCUIT

- Turn ignition switch OFF.

- Check continuity between ABS actuator and electric unit (control unit) connector E125 terminals and ground.

Is the inspection result normal? YES >> GO TO 11.

NO >> Repair or replace malfunctioning components.

11.CHECK WHEEL SENSOR INPUT VOLTAGE

- Connect ABS actuator and electric unit (control unit) connector E125.

- Turn ignition switch ON.

- Check voltage between suspect wheel sensor harness connector terminals.

Is the inspection result normal? YES >> Replace wheel sensor. Refer to BRC-132, "FRONT WHEEL SENSOR : Removal and Installation" or BRC-134, "REAR WHEEL SENSOR : Removal and Installation". Then, GO TO 12.

NO >> Replace ABS actuator and electric unit (control unit). Refer to BRC-136, "Removal and Installation".

12.CONFIRM REPAIR

With CONSULT

With CONSULT

- Clear all DTCs.

- Perform DTC confirmation procedure. Refer to BRC-74, "DTC Logic".

Does DTC C1105, C1106, C1107 or C1108 reset? YES >> Replace ABS actuator and electric unit (control unit). Refer to BRC-136, "Removal and Installation".

NO >> Inspection End.

C1105, C1106, C1107, C1108 wheel sensor

C1105, C1106, C1107, C1108 wheel sensor

DTC Logic

DTC DETECTION LOGIC

DTC

Display Item

Malfunction detected condition

Possible causes

C1105

RR RH SENSOR-2

When distance between rear ...

Other materials:

Basic inspection

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.INTERVIEW CUSTOMER

Interview the customer to obtain as much information as possible about the

conditions and environment under

which the malfunction occurred.

>> GO TO 2.

2.SYMPTOM CHECK

Verify symptoms.

...

NISSAN Intelligent Key® battery discharge

(if so equipped)

NISSAN Intelligent Key® battery discharge

If the battery of the NISSAN Intelligent Key® is

discharged, or environmental conditions interfere

with the Intelligent Key operation, start the engine

according to the following procedure:

Place the shift lever in the P (Park) position.

...

Basic inspection

DIAGNOSIS AND REPAIR WORKFLOW

Trouble Diagnosis Flow Chart

Trouble Diagnosis Procedure

INTERVIEW WITH CUSTOMER

Interview with the customer is important to detect the root cause of CAN

communication system errors and to

understand vehicle condition and symptoms for proper trouble diagnosis ...